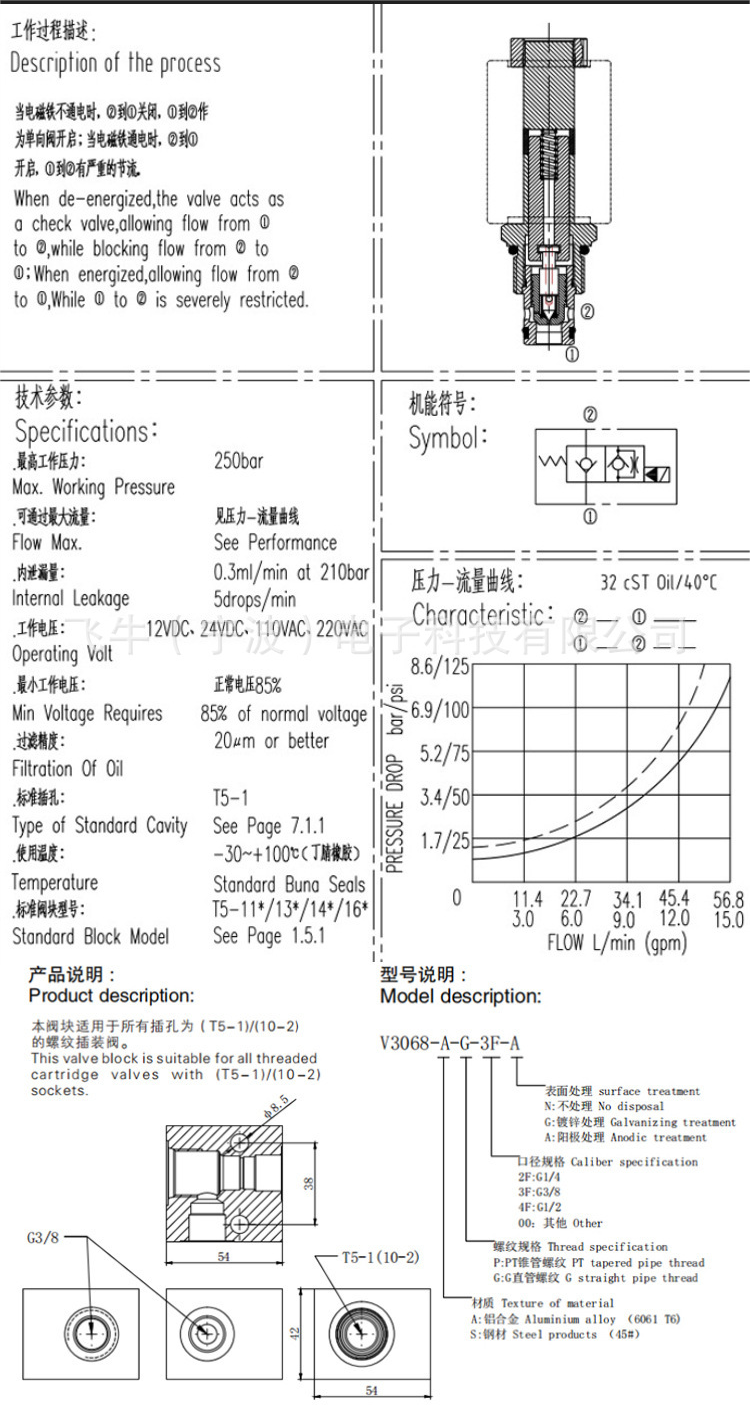

Two-way electric switch pressure relief valve with base DHF10-220

Details

Warranty:1 Year

Brand Name:FLYING BULL

Place of Origin:Zhejiang, China

Weight:0.5

Dimension(L*W*H):standard

Valve type:Hydraulic valve

Maximum pressure:250bar

PN:25

Material body:carbon steel

Type of attachment:screw thread

Type of drive:electromagnetism

Type (channel location):General formula

Function function:Pressure relief

Sealing material:valve body

Pressure environment:ordinary pressure

Flow direction:one-way

Applicable industries:machinery

Points for attention

The common fault phenomena of electromagnetic ball valve in use mainly include the following:

1) The valve core does not move

The main reasons for the non-movement of the valve core are electromagnet failure, valve core clamping, oil change and reset spring failure.

2) Leakage

Mainly including internal leakage and external leakage;

3) large pressure loss

It is mainly caused by the excessive actual flow, the size error of the shoulder of the valve core or the undercut groove of the valve body, and the improper movement of the valve core.

4) magnetic leakage

The surface of the electromagnetic coil is defective, which leads to the change of magnetic flux passing through the coil;

5) Shock and vibration

The movement speed of the valve core is too high or the screw fixing the solenoid valve is loose, resulting in impact and vibration.

The failure mechanism of electromagnetic ball valve caused by mechanical physics mainly includes:

1.The working pressure difference exceeds the standard: when the electromagnetic ball valve is used in the system, it does not meet the pressure difference design requirements required by the manufacturer for the maximum (minimum) medium inlet and outlet;

2. Failure of sealing ring: elastic rubber becomes hard or decays and decomposes;

4.Foreign matter: irrelevant substances from outside enter the interior of the electromagnetic ball valve, which affects the action of the electromagnetic ball valve and causes jamming or lax sealing;

5.Lubrication failure: the lubricant used has been degraded or there is improper lubrication;

6.Other failure: only one failure occurred;

7.Unexplained reason: Failure confirmed by insufficient information.

Product specification

Company details

Company advantage

Transportation

FAQ