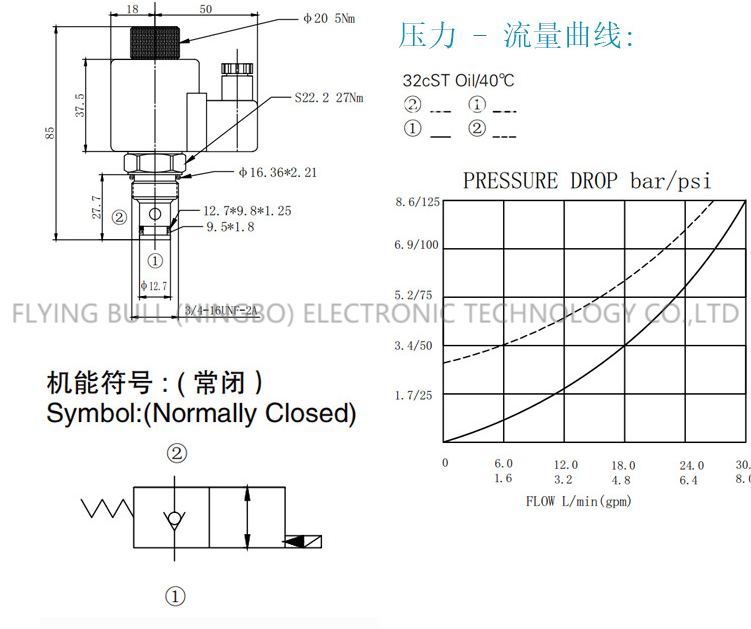

Two-position two-way hydraulic threaded cartridge valve DHF08-222

Details

Functional action:Reversing type

Lining material:alloy steel

Sealing material:rubber

Temperature environment:60

Flow direction:commutate

Optional accessories:coil

Applicable industries:machinery

Type of drive:electromagnetism

Applicable mediump:etroleum products

Product introduction

These points should be considered when buying hydraulic cartridge valves.

(1) Valve core structure: The key is based on the selected total flow characteristics and unbalanced feeling.

(2) Abrasion resistance: When the liquid medium is a solution with high concentration of abrasive particles, the data inside the valve should be hard.

(3) Corrosion resistance: Because the medium is corrosive, select and construct a simple miniature relief valve as much as possible.

(4) Temperature and working pressure of the medium: When the temperature and pressure of the medium are high and change greatly, valves with small changes in temperature and working pressure of the raw materials of the valve core and high-pressure gate valve should be used.

(5) Avoid flash evaporation and cavitation: flash evaporation and cavitation only occur in liquid media. In the actual production process, flash evaporation and cavitation will produce vibration and noise, reducing the service life of the valve, so when selecting the valve, it is necessary to avoid flash evaporation and cavitation caused by the valve.

Selection of actuator for safety relief valve: In order to make the control valve work normally, the applicable actuator should be able to generate enough output force to ensure the relative high sealing and opening of the valve. Generally, there is no calibration torsion spring for pneumatic, hydraulic and electric actuators with dual functions. The magnitude of the efficacy force has nothing to do with its operating orientation, so the key point in selecting the actuator is to find out the large output force and the rotating torque of the motor. For the single-function pneumatic actuator, the derived force is related to the opening of the valve, and the force generated on the regulating valve will also endanger the characteristics of fitness exercise, so it is stipulated to create a force balance in all the opening categories of regulating valves.

Clarify the types of actuators: after the derived force of actuators is clear, select the corresponding actuators according to the requirements of processing technology application conditions. When there are explosion-proof regulations on the spot, pneumatic actuators should be used. From the perspective of environmental protection and energy saving, electric actuators should be used as far as possible.(1) Valve core structure: The key is based on the selected total flow characteristics and unbalanced feeling.

Product specification

Company details

Company advantage

Transportation

FAQ