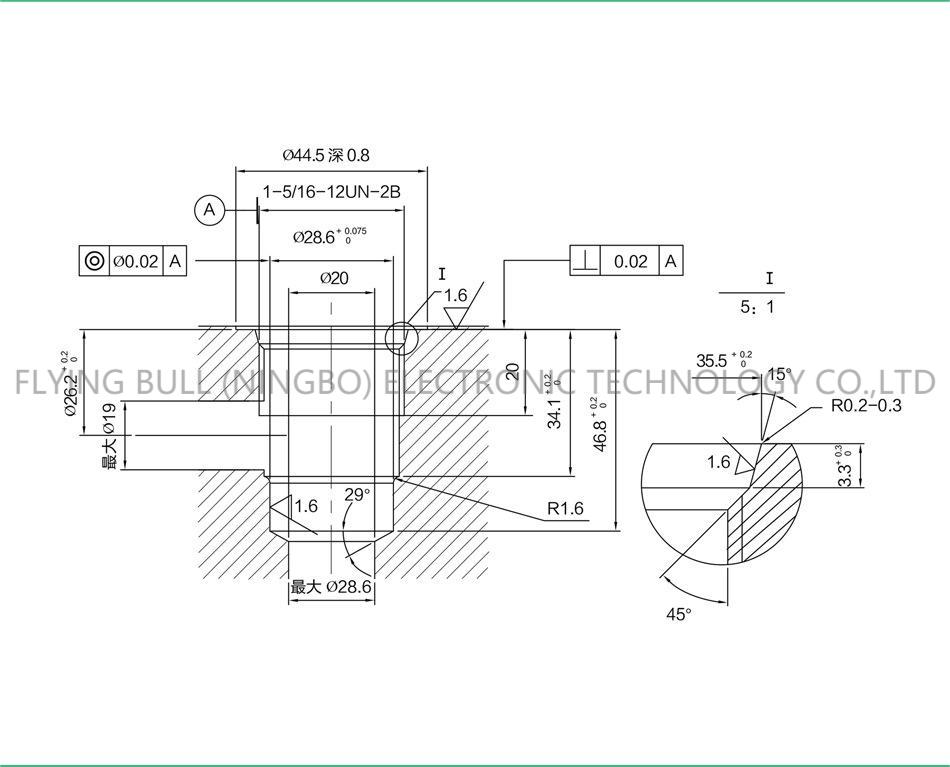

Two-position two-way hydraulic cartridge valve SV16-22

Details

Valve action:commutate

Type (channel location):Two-way formula

Functional action:Normally closed type

Lining material:alloy steel

Sealing material:Buna-N rubber

Temperature environment:normal atmospheric temperature

Flow direction:two-way

Optional accessories:coil

Applicable industries:machinery

Type of drive:Hydraulic control

Applicable medium:petroleum products

Product introduction

When filling the pressure regulating relief valve, pay attention to the problem of the gate valve in the main switch position of the power supply. Valve maintenance is generally in the open position, and it is selected to be closed for maintenance under special circumstances. Other gate valves can't be convicted of opening. Under maintenance conditions, the stop valve should be closed as far as possible to ensure that grease fills the sealed pipe trench along the sealing ring. If it is opened, the sealing grease will immediately fall into the flow passage or valve cavity, resulting in consumption.

Operation and maintenance of pressure regulating overflow valve

1. The purpose of using and maintaining the electromagnetic cartridge valve is to improve the service life of the oxygen cut-off valve and ensure a reliable switch.

2. The external thread of the valve stem often rubs against the valve stem nut and is coated with a small amount of yellow dry oil, molybdenum disulfide or flake graphite, which has the effect of lubricating oil.

3. For copper threaded ball valves that are not frequently opened and closed, turn the spindle of the machine tool on time, and add lubricant to the external thread of the valve stem to avoid biting.

4, outdoor oxygen globe valve, to add a protective sleeve on the valve stem, to avoid rain and snow weather.

5. If the gate valve is industrial equipment and needs to be moved, the gearbox should be refueled on time.

6, continue to clean the oxygen cut-off valve.

7. Always check and maintain the consistency of the prefabricated components of the oxygen cut-off valve. If the fixed nut of the machine tool spindle falls off, it should be completely matched and cannot be used, otherwise it will grind to the upper end of the garden valve stem, gradually lacking the reliability of mutual matching and even unable to run.

8, don't rely on oxygen cut-off valve for other lifting, don't stand up on the oxygen cut-off valve.

9. The valve stem, especially a part of external thread, should be cleaned frequently. Lubricating fluid soiled by dust should be replaced. Because the dust contains hard stains, it is very easy to destroy the external thread and the surface layer of the valve stem, which seriously endangers the service life of the explosion-proof cartridge valve.

Product specification

Company details

Company advantage

Transportation

FAQ