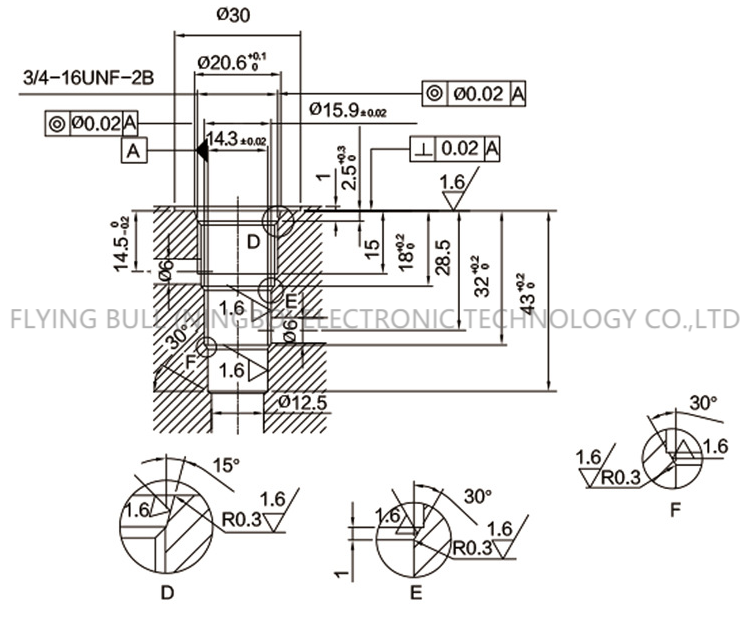

Two-position three-way cartridge solenoid valve SV08-30

Details

Valve action:directional valve

Type (channel location):Two-position tee

Functional action:directional valve

Lining material:alloy steel

Temperature environment:normal atmospheric temperature

Flow direction:commutate

Optional accessories:coil

Applicable industries:machinery

Type of drive:electromagnetism

Applicable medium:petroleum products

Points for attention

1. Working reliability

Refers to whether the electromagnet can be reliably commutated after being energized and can be reliably reset after being powered off. Solenoid valve can only work normally within a certain flow and pressure range. The limit of this working range is called commutation limit.

2. Pressure loss

Because the opening of the solenoid valve is very small, there is a great pressure loss when the liquid flows through the valve port.

3. Internal leakage

At different working positions, under the specified working pressure, the leakage from the high pressure chamber to the low pressure chamber is the internal leakage. Excessive internal leakage will not only reduce the efficiency of the system and cause overheating, but also affect the normal work of the actuator.

4. Commutation and reset time

The commutation time of AC solenoid valve is generally 0.03 ~ 0.05 s, and the commutation impact is great; The commutation time of DC solenoid valve is 0.1 ~ 0.3 s, and the commutation impact is small. Usually the reset time is slightly longer than the commutation time.

5. Commutation frequency

Commutation frequency is the number of commutations allowed by the valve in unit time. At present, the commutation frequency of solenoid valve with single electromagnet is generally 60 times /min.

6. Service life

The service life of solenoid valve mainly depends on electromagnet. The life of wet electromagnet is longer than that of dry electromagnet, and that of DC electromagnet is longer than that of AC electromagnet.

In petroleum, chemical, mining and metallurgical industries, the six-way reversing valve is an important fluid reversing device. The valve is installed in the pipeline conveying lubricating oil in the thin oil lubrication system. By changing the relative position of the sealing assembly in the valve body, the channels of the valve body are connected or disconnected, so as to control the reversing and start-stop of the fluid.

Product specification

Company details

Company advantage

Transportation

FAQ