Threaded plug-in one-way pressure maintaining valve DF16-02

Details

Warranty:1 Year

Showroom Location:None

Brand Name:Flying Bull

Place of Origin:Zhejiang, China

Weight:1

Valve type:Hydraulic valve

Material body:carbon steel

Type of attachment:screw thread

Pressure environment:ordinary pressure

Applicable industries:machinery

Applicable medium:petroleum products

Sealing material:O-ring

Colour:metallochrome

Type:Flow valve

Type of drive:manual

Type (channel location):Straight through type

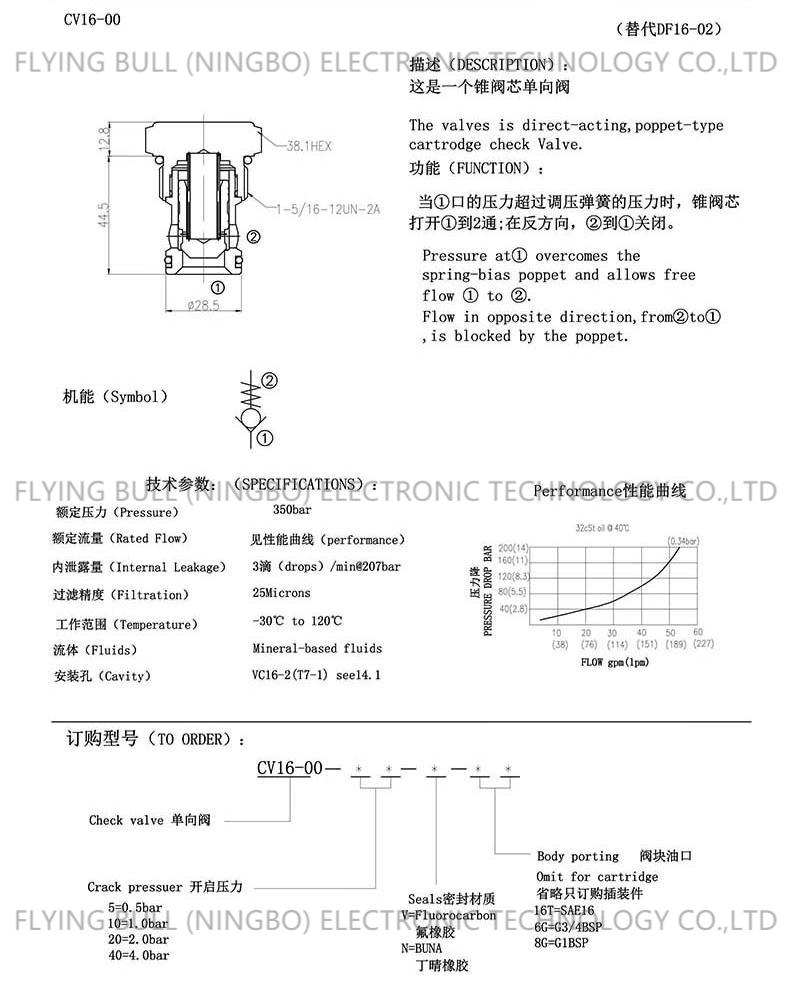

Product introduction

The nominal pressure of the safety valve is determined by the operating pressure, the service temperature range of the safety valve is determined by the operating temperature, the constant pressure range of the spring or lever is determined by the calculated constant pressure value of the safety valve, the material and structural type of the safety valve are determined according to the service medium, and the throat diameter of the safety valve is calculated according to the discharge capacity of the safety valve. The following are the general rules for the selection of safety valves.

(l) Hot water boilers generally use unsealed micro-opening safety valves with wrenches.

(2) Steam boilers or steam pipelines generally use open safety valves with wrenches.

(3) For liquid incompressible media such as water, a closed micro-opening safety valve or a safety relief valve is generally used.

(4) High-pressure water supply generally uses closed full-open safety valves, such as high-pressure water supply heaters and heat exchangers.

(5) Gas and other compressible media generally use closed full-open safety valves, such as gas storage tanks and gas pipelines.

(6) Class E steam boilers generally use dead weight safety valves.

(7) Pulsed safety valves are generally used for large-caliber, large-displacement and high-pressure systems, such as desuperheating and decompression devices and power station boilers, as shown in Figure 8.

(8) Built-in safety valves are generally used for train tankers, car tankers and storage tanks transporting liquefied gas, as shown in Figure 4.

(9) The hydraulic safety valve is generally used at the top of the oil tank, which needs to be used in conjunction with the breathing valve.

(10) Pilot safety valves are generally used for underground drainage or natural gas pipelines, as shown in Figure 6.

(11) The safety return valve is generally used on the liquid phase return pipeline at the pump outlet of LPG station tank.

(12) Negative pressure or systems that may generate negative pressure during operation generally use vacuum negative pressure safety valves.

(13) Bellows safety valves are generally used for containers or pipeline systems with large back pressure fluctuation and toxic and flammable.

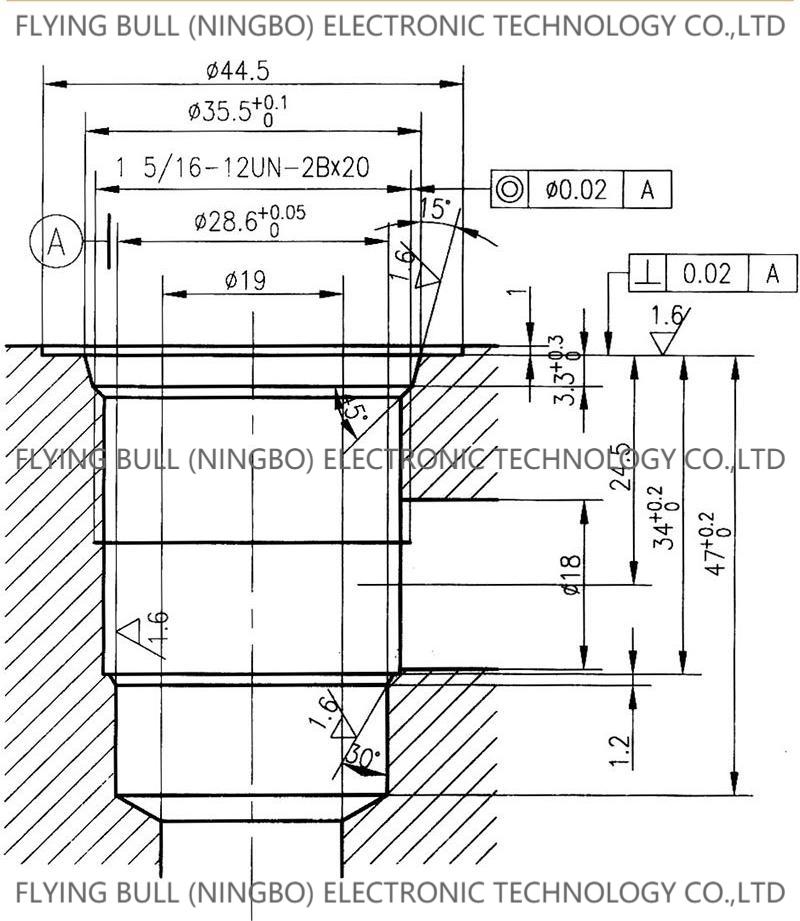

Product specification

Company details

Company advantage

Transportation

FAQ