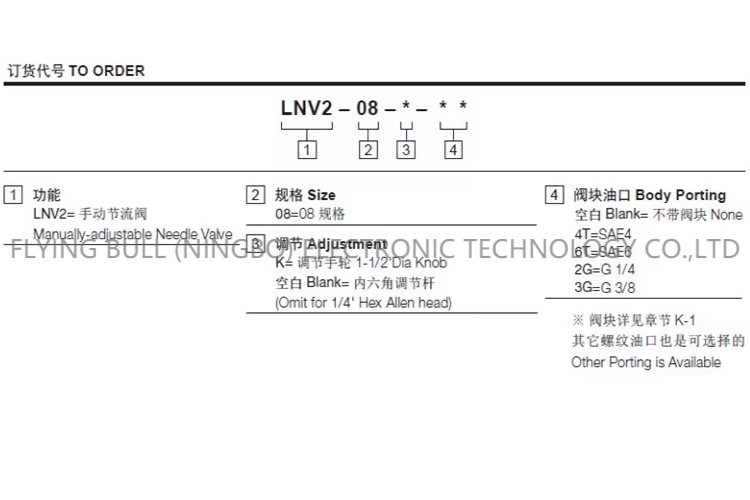

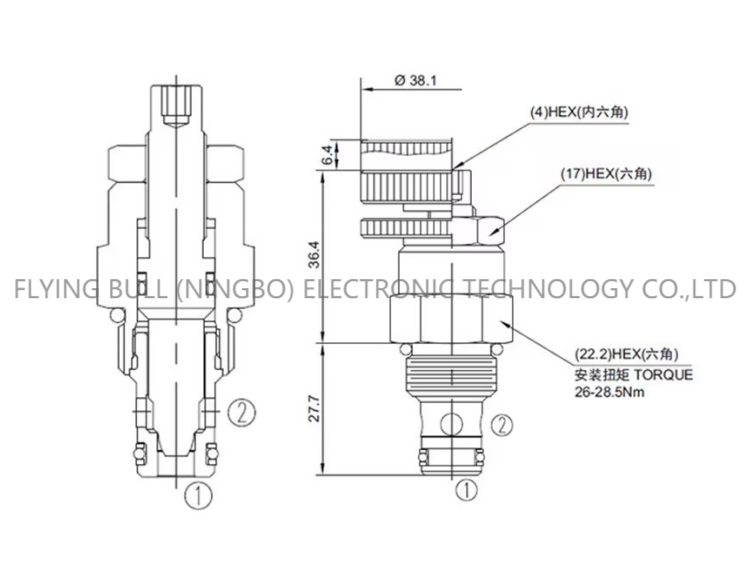

Threaded plug-in flow control throttle valve LNV2-08

Details

Valve action:regulate pressure

Type (channel location):Direct acting type

Lining material:alloy steel

Sealing material:rubber

Temperature environment:normal atmospheric temperature

Applicable industries:machinery

Type of drive:electromagnetism

Applicable medium:petroleum products

Points for attention

product performance

1. The flow can be set according to the design or actual requirements, which avoids blind adjustment and simplifies the complex network adjustment work into simple flow distribution;

2. Completely overcome the uneven cold and heat of the system and improve the quality of heating and cooling;

3. The design workload is reduced, and the complicated hydraulic balance calculation of the pipe network is not needed;

4. Eliminate the flow redistribution when switching between multiple heat sources and heat sources in the pipe network.

5. The rotor part of the flow movement is made of agate bearing, which is wear-resistant and does not rust;

6. The communicator and sensor on the valve body have no power supply, and the display adopts fully sealed structure with long service life;

7. Automatically sleep when not working to save power, with a designed service life of more than ten years;

Selection of flow control valve

Can be selected according to the equal diameter of the pipeline.

It can be selected according to the maximum flow and the flow range of the valve.

Structural features:

The 400X flow control valve consists of a main valve, a flow control valve, a needle valve, a pilot valve, a ball valve, a micro filter and a pressure gauge. Hydraulic automatic operation is used to control and adjust the opening of the main valve, so that the flow through the main valve remains unchanged. This hydraulic control valve is self-controlled by hydraulic power, without other devices and energy sources, with simple maintenance and stable flow control. This series of valve products are widely used in high-rise buildings, living quarters and other water supply network systems and urban water supply projects.

Working principle:

When the valve feeds water from the inlet end, the water flows through the needle valve into the main valve control room, and flows out of the main valve control room to the outlet through the pilot valve and the ball valve. At this time, the main valve is in a fully open or floating state. By setting the flow regulating valve at the upper part of the main valve, a certain opening can be set for the main valve. By adjusting the needle valve opening and the pilot valve spring pressure, the main valve opening can be kept at the set opening, and the pilot valve can be automatically adjusted when the pressure changes to keep the flow unchanged.

Product specification

Company details

Company advantage

Transportation

FAQ