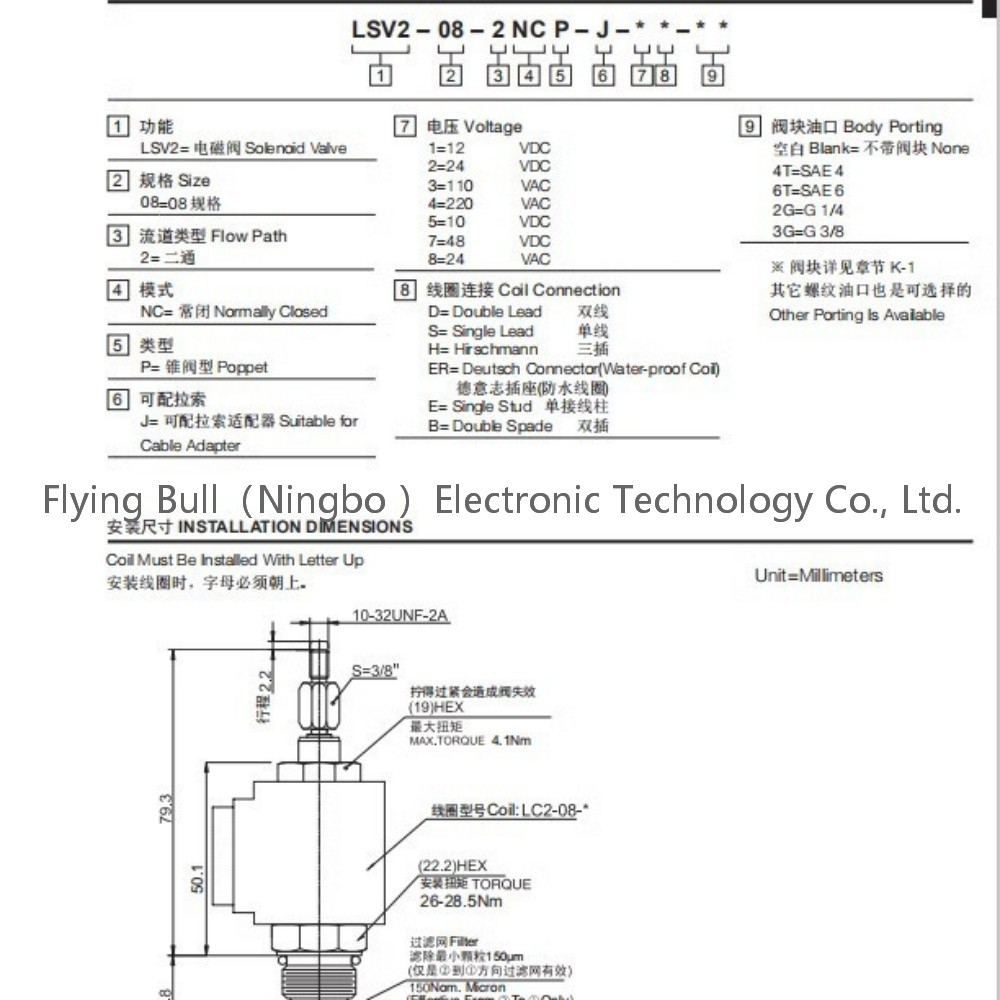

Threaded cartridge valve two-position two-way solenoid valve normally closed LSV2-08-2NCP-J-24V

Details

Sealing material:Direct machining of valve body

Pressure environment:ordinary pressure

Temperature environment:one

Optional accessories:valve body

Type of drive:power-driven

Applicable medium:petroleum products

Points for attention

The working principle of threaded cartridge valve is to drive the spool to change direction by electromagnetic force to realize the conversion from electricity to force. Specifically, the threaded cartridge valve is a two-position four-way threaded cartridge electromagnetic directional valve, which is a direct-acting valve with a slide valve core. When the electromagnetic coil is energized, it will produce a magnetic field, and the armature will be pulled in the magnetic field, pulling the valve core to move to reverse. The electromagnetic force overcomes the damping force (including spring force, hydraulic pressure and friction force), so that the valve core switches and maintains the electric position. At this time, the oil outlet T is connected with the working oil port A, and the oil inlet P is connected with the working oil port B; When the coil is deenergized, the restoring spring force returns the valve core to the deenergized position, at which time the oil outlet T is connected with the working oil port B, and the oil inlet P is connected with the working oil port A.. In addition, the working principle of hydraulic threaded cartridge valve involves the pressure pilot main valve. Pressure oil enters from port and acts on the main valve core. When the force is greater than the pre-tightening pressure of the main spring, the main valve core is pushed away and the pressure oil overflows from the port . The spring cavity is communicated with the port , but not with the outlet , so the pressure of the outlet does not affect the switching pressure. The characteristics of threaded cartridge valve include strong versatility, small volume and low cost. Because of its universal design, valves with different functions can choose the same standard valve cavity, which reduces the processing cost of the valve block. The characteristics of small volume and low cost make cartridge valves widely used in hydraulic systems, especially in places with limited space.

Product specification

Company details

Company advantage

Transportation

FAQ