Thread cartridge valve XYF10-06 for crane construction machinery

Points for attention

Basic causes of noise and vibration

1 Noise generated by holes

When air is sucked into the oil for various reasons, or when the oil pressure is lower than atmospheric pressure, some air dissolved in the oil will precipitate to form bubbles. These bubbles are larger in the low-pressure area, and when they flow with the oil to the high-pressure area, they are compressed, and the volume suddenly becomes smaller or the bubbles disappear. On the contrary, if the volume is originally small in the high-pressure area, but it suddenly increases when it flows to the low-pressure area, the volume of bubbles in oil changes rapidly. The sudden change of bubble volume will produce noise, and because this process occurs in an instant, it will cause local hydraulic impact and vibration. The velocity and pressure of the pilot valve port and the main valve port of the pilot relief valve vary greatly, and cavitation is easy to occur, resulting in noise and vibration.

2 Noise generated by hydraulic impact

When the pilot relief valve is unloaded, the pressure impact noise will occur due to the sudden drop of the pressure in the hydraulic circuit. The more high-pressure and large-capacity working conditions, the greater the impact noise, which is caused by the short unloading time of the overflow valve and the hydraulic impact. During unloading, the pressure changes suddenly due to the rapid change of oil flow rate, resulting in the impact of pressure waves. Pressure wave is a small shock wave, which produces little noise, but when it is transmitted to the system with oil, if it resonates with any mechanical part, it may increase vibration and noise. Therefore, when hydraulic impact noise occurs, it is usually accompanied by system vibration.

The main requirements for the relief valve are: large pressure regulating range, small pressure regulating deviation, small pressure swing, sensitive action, large overload capacity and low noise.

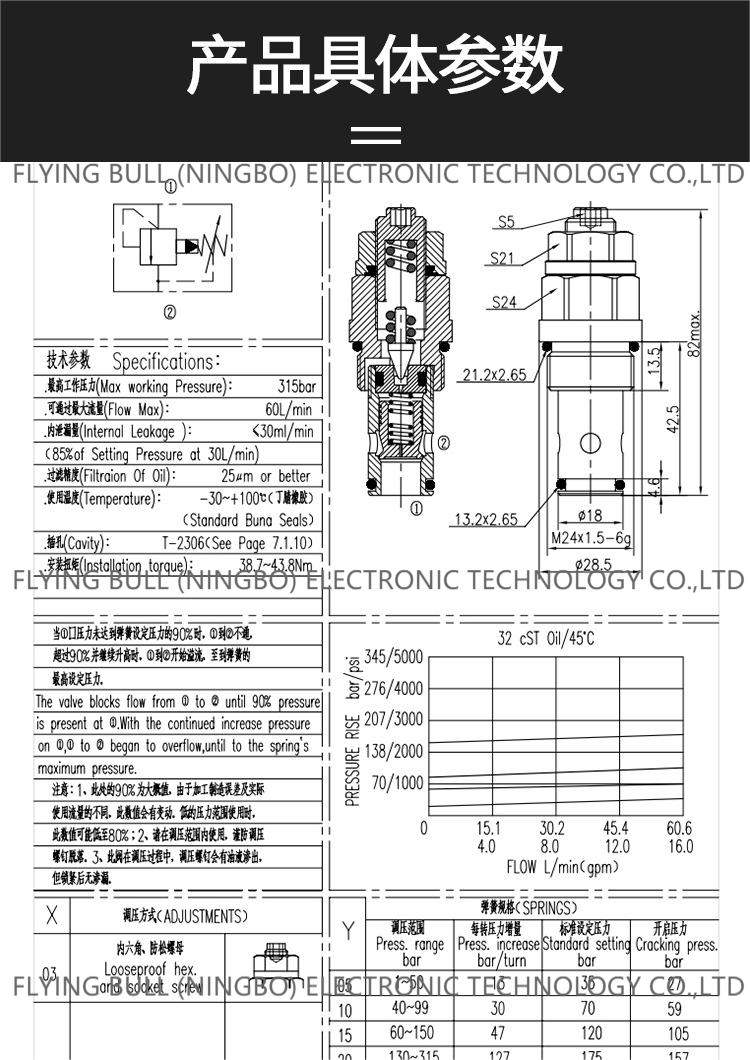

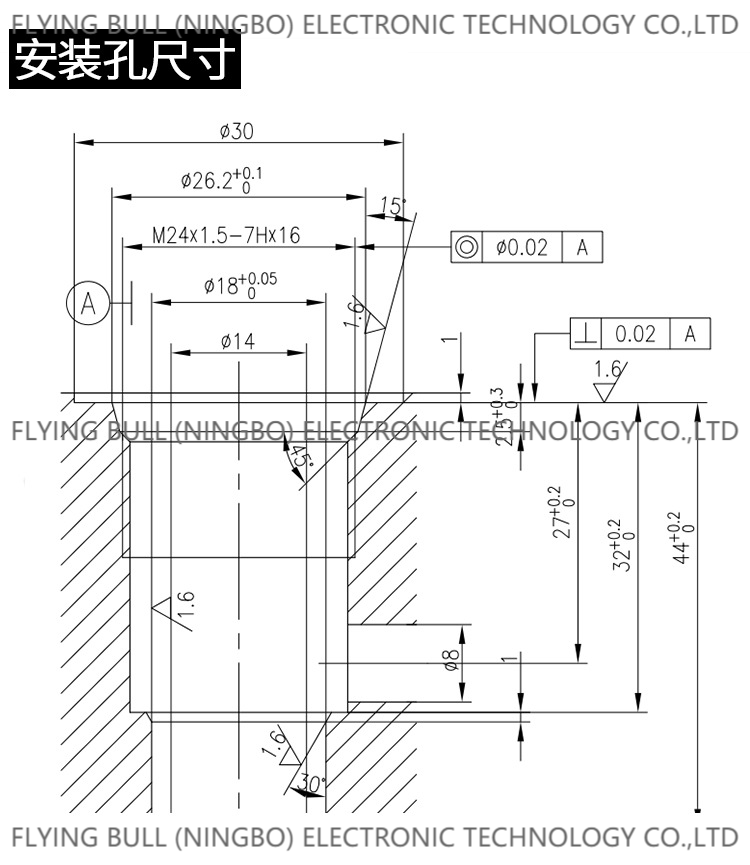

Product specification

Company details

Company advantage

Transportation

FAQ