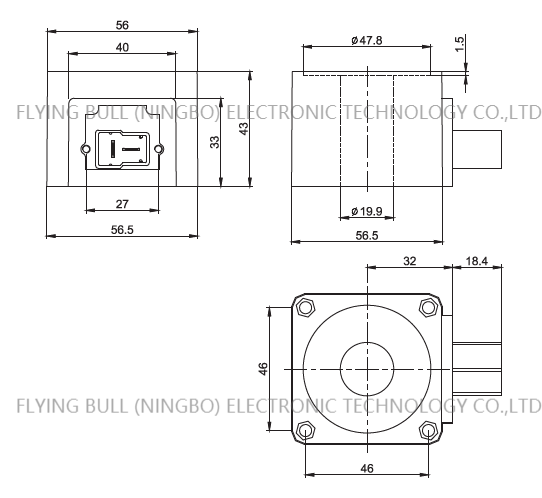

Thermosetting solenoid valve coil FN20432 for automobile

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Product name: Solenoid coil

Normal Voltage: DC24V DC12V

Normal Power (DC): 15W

Insulation Class: H

Connection Type: 6.3×0.8

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB732

Product Type: FXY20432

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

What factors will affect the life of solenoid valve coil?

Although the service life of solenoid valve coil is generally determined by the quality of the coil itself, the actual service life of Keweina solenoid valve coil will also be affected by many application factors.

Factor 1: the heating problem in the use of the coil.

Although the solenoid valve coil will be heated under normal application conditions because it needs to be in contact with electric power, if it is heated at a higher temperature due to various external factors, its service life will be shortened because of this heat.

Factor 2: Bad power use.

In the application process of solenoid valve coil, if there are bad application problems in power supply, such as excessive voltage or current supplied by power supply, it will also have a certain adverse impact on the life of the coil.

Factor 3: Long-term contact with excessively humid air.

If you use the solenoid valve coil and make it contact with very humid air for a long time, it will also have a certain adverse effect on the service life of the coil.

The life of solenoid valve coil will be affected by the above application factors, so in order to ensure that everyone's coil can achieve long-term application, we need to pay attention to avoid the existence of these adverse application factors.

The solenoid valve coil terminals are all flooded due to poor sealing, and the corrosion of the terminals is all on the positive electrode, while the negative electrode is intact.

From this, it can be judged that the primary reason for the corrosion of the terminal is the poor sealing of the solenoid valve coil and the water inflow. However, due to the bad working conditions in the field, the impact of coal blocks on the coil is inevitable, so there is no guarantee that there is no water at the coil terminal.

Product picture

Company details

Company advantage

Transportation

FAQ