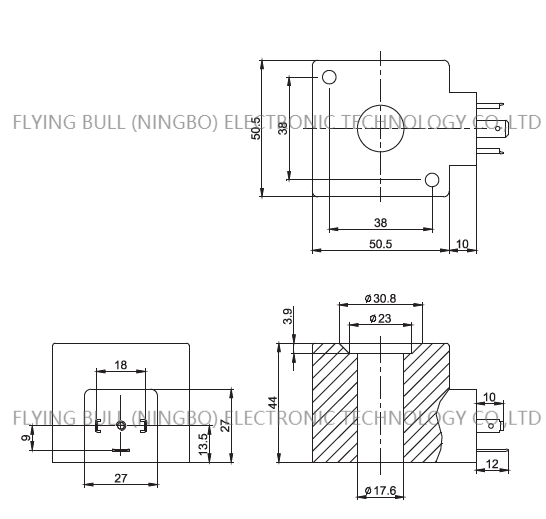

Thermosetting Hydropneumatic Electromagnetic Coil K23D-3H

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Product name: Solenoid coil

Normal Voltage: AC220V DC110V DC24V

Normal Power (AC): 22VA

Normal Power (DC): 10W

Insulation Class: H

Connection Type: DIN43650A

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB713

Product Type: K23D-3H

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

"What is the great help of electromagnetic coil to the development of technology? The introduction shows that the development of electromagnetic coil in the direction of simplification is from fine to simple, and only simple can be circulated for a long time. This is also the permanent pursuit of scientists and engineers.

(1) Simplifying the control loop In the past,

a large number of actuators used pneumatic and electric control loops, which increased the complexity of the system, while the pilot solenoid valve formed a control loop using the working medium itself in the valve, with a very simple structure. In the past, many technical parameters of solenoid valves at home and abroad were still limited, but now the size of solenoid valves in China has been expanded to 30Omm;; The medium temperature is as low as 200℃ and as high as 450℃; The working pressure is from vacuum to 25MPa. The action time ranges from ten seconds to several milliseconds. The new development of these technologies can completely replace the original bulky and expensive two-position control quick cut-off valve, pneumatic on-off valve and electric on-off valve, and can also partially replace the continuously adjusted pneumatic and electric regulating valves. (How to better meet the adjustment accuracy requirements will be discussed below). Foreign textile, light industry, urban construction and other industries have largely switched to solenoid valves, while metallurgical, chemical and other industries have taken the lead in using more and more solenoid valves in auxiliary systems.

(2) Simplify the pipeline system.

When the automatic control valve works, some auxiliary valves and pipe fittings must be used on the pipeline. For example, the isolation bypass shown in Figure 1 is a typical installation method, which requires three manual valves, of which manual valve 1 is a bypass valve, which is manually reserved. The manual valves 2 and 3 are isolation valves to ensure the online maintenance of the automatic control valve 5. Of course, there must be two tees 4 and movable joints 6. This kind of pipeline system takes up a lot of space, takes time to install and is easy to leak. ZDF series multi-function solenoid valves cleverly omit these additional accessories and still have the function of isolating bypass, so they won the Geneva International Gold Award for New Technology. A filter should be installed in front of the automatic control valve. When multiple automatic control valves are used together, it is often necessary to install one-way valves to prevent interference between pipelines. Now, one-way solenoid valve, combined solenoid valve and solenoid valve with filter have all played a role in simplifying the pipeline."

Product picture

Company details

Company advantage

Transportation

FAQ