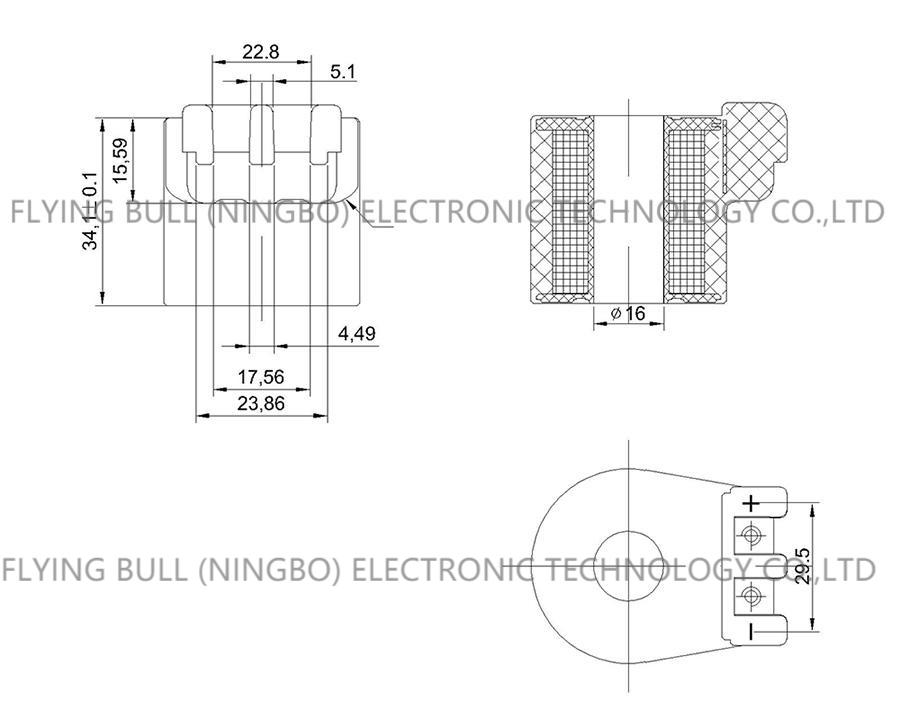

Thermosetting DIN43650Al connection electromagnetic coil SB1001

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Product name: Solenoid coil

Normal Voltage: AC220V DC24V

Normal Power (AC): 18VA

Normal Power (DC): 13W

Insulation Class: H

Connection Type: DIN43650A

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB433

Product Type: TM30

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Basic requirements for producing electromagnetic coils Introduce the basic requirements for producing electromagnetic coils:

1, product design should fully consider the universality and standardization requirements of parts; Failure mode analysis should be carried out for products matched with automobiles and products required by customers;

2. The enameled wire supplier shall be required to provide material reports for each batch, and provide qualified third-party electrical and thermal performance test reports at least once a year;

3. In the production process, foolproof measures should be formulated to prevent missing and wrong installation and ensure stable quality; Should be equipped with automatic production equipment for winding and assembly;

4, should be equipped with special resistance, turn-to-turn withstand voltage and power frequency withstand voltage integrated test equipment, improve efficiency, reduce the influence of human factors. Standard scope: This standard is applicable to solenoid valve coils for fluid control with AC 50Hz or 60Hz, rated voltage of 600V and below, and DC rated voltage of 240V and below. This standard is not applicable to explosion-proof coils.

Types and application environment of electromagnetic coils There are mainly the following types of electromagnetic coils: thermoplastic coils, thermosetting coils, explosion-proof coils, waterproof coils and paint-dipped coils. Among them, thermoplastic coil and thermosetting coil belong to plastic-sealed electromagnetic coil. Thermoplastic coil has better weather resistance and toughness, thermosetting coil has higher temperature resistance grade, smaller shrinkage during injection molding and smoother appearance.

Operating environment of electromagnetic coil:

1. Explosion-proof coil: ① Suitable for underground coal mines and other environments with explosive gas; ② The medium temperature shall not exceed 60℃, and the exposed temperature of the valve body shall not exceed 130℃.

2, waterproof coil: soaked in water.

3. Paint-dipped coil: an environment with no requirements for waterproof and dustproof.

Product picture

Company details

Company advantage

Transportation

FAQ