Thermosetting Connection Mode Hylon Series 0927 Electromagnetic Coil

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Product name: Solenoid coil

Normal Voltage: AC220V AC110V DC24V DC12V

Normal Power (AC): 9VA 15VA 20VA

Normal Power (DC): 11W 12W 15W

Insulation Class: F, H

Connection Type: DIN43650A

Other special voltage: Customizable

Other special power: Customizable

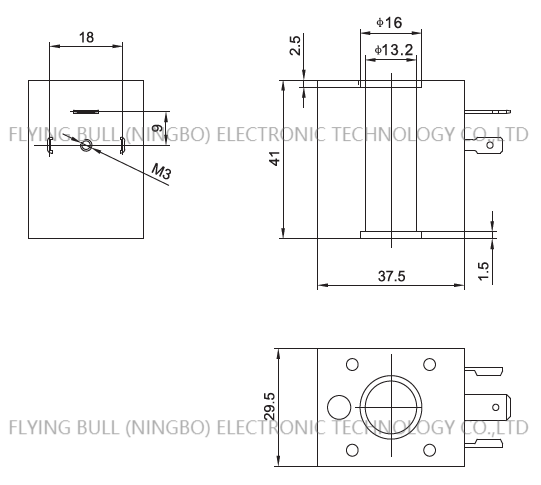

Product No.: SB050

Product Type: 200

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Why can't you touch the air-core inductance coil?

Due to the high frequency of the circuits used in the air-core inductance coil, a weak change in the parameters of the inductance coil will cause a great change in the frequency of the circuit composed of it, which will make the circuit unable to work or the data it provides inaccurate. The main factors that affect the change of inductance are magnetic medium, coil density (tightness), coil turns and wire diameter, wire data, etc. If you touch it with your fingers, it will cause the change of magnetic medium (originally air, but now it is influenced by your fingers) and coil density (the tightness has also changed), so you can't touch the hollow inductor.

Definition of enameled wire of electromagnetic coil (self-adhesive enameled wire & non-self-adhesive enameled wire);

Enamelled wire of electromagnetic coil is made by coating a layer of insulating coatings on a conductor with high purity and high conductivity, that is, conductor+insulating paint = non-self-adhesive enameled wire conductor+insulating paint+adhesive layer = self-adhesive enameled wire.

Inductive coil is a device that works by using the principle of electromagnetic induction. When a current flows through a wire, a certain electromagnetic field will be generated around the wire. It is regularly wound on a coil. Let's talk about the winding method of inductance coil:

1. Single layer winding method

The turns of the inductance coil are wound on the outer surface of the insulated pipe in a single layer. The single layer winding method can be divided into indirect winding and tight winding. Indirect winding is generally used in some high-frequency resonant circuits, because this winding method can reduce the capacitance of the high-frequency resonant line diagram and stabilize some of its characteristics. The tight winding mode is based on some coils with relatively small resonant coil range.

2, multilayer winding method

The inductance of the coil is relatively large, and the winding method of the coil is multi-layer, which includes two types: dense winding and honeycomb winding. The dense winding method is closely arranged and needs layer-by-layer distribution, and the capacitance generated by the winding coil is relatively large. The honeycomb winding method is arranged at a certain angle, and its arrangement is not very flat, but compared with the dense winding method, its capacitance is relatively small. Some high-voltage resonant circuits need to meet the current value and the withstand voltage between the coils when winding the inductor. When winding the inductor, we should also consider the heat of the coil.

Product picture

Company details

Company advantage

Transportation

FAQ