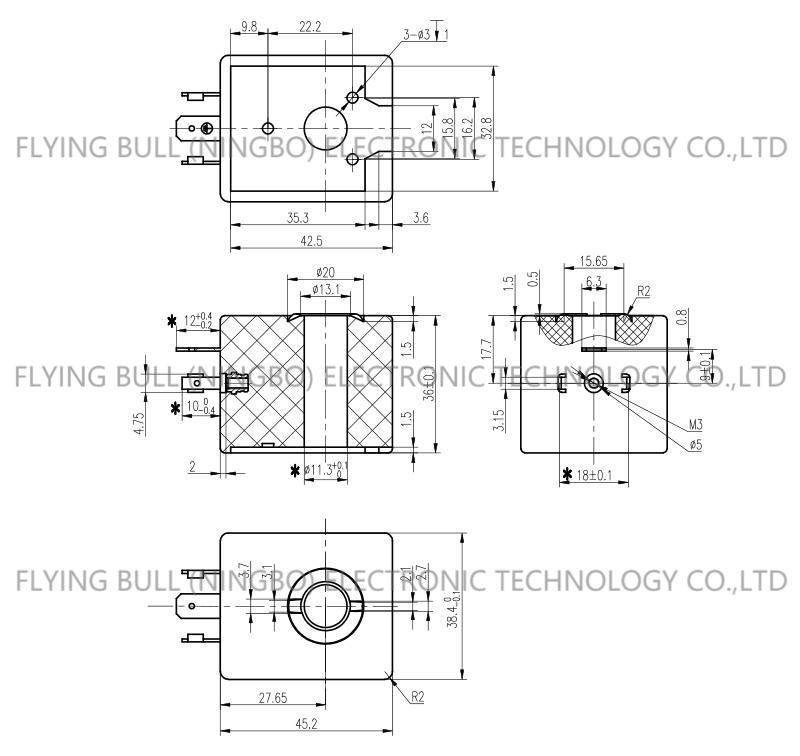

Thermosetting DIN43650A connection electromagnetic coil SB254/A044

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Product name: Solenoid coil

Normal Voltage: AC220V AC110V DC24V DC12V

Normal Power (AC): 20VA

Normal Power (DC): 21W

Insulation Class: H

Connection Type: DIN43650A

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB254

Product Type: A044

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Quality factor q of inductance coil

1.The factor q is an important parameter to express the coil quality. The size of Q indicates the loss of inductance coil. The larger the Q, the smaller the loss of the coil. On the contrary, the greater the loss.

2.The quality factor Q is defined as the ratio of the inductance of the coil to the DC resistance of the coil when the coil works at a certain frequency AC voltage. It can be expressed by the formula as follows:

3.Where: W-working angular frequency L-coil inductance R-total loss resistance of coil

4.According to different occasions, the requirements for quality factor Q are also different. For the inductance coil in the tuning loop, the q value is higher, because the higher the q value, the smaller the loss of the loop and the higher the efficiency of the loop; For the coupling coil, the q value can be lower; For low-frequency or high-frequency chokes, there is no requirement.

5.In fact, the improvement of Q value is often limited by some factors, such as the DC resistance of the conductor, the dielectric loss of the bobbin, the loss caused by the core and the shield, and the skin effect when working at high frequency. Therefore, it is impossible to make the Q value of the coil very high. Usually, the Q value is several tens to one hundred, and the highest is only 500.

6.When selecting the magnetic core, the requirements of working frequency and Q value should be mainly considered. When the general working frequency is below 1MHz, the magnetic core made of manganese-zinc ferrite should be properly used; When the working frequency is higher than 1MHz, the magnetic core made of Ni-Zn-Fe-O material should be selected. Under the condition of high Q value and low working frequency, the larger size magnetic core should be selected.

7.When selecting the magnetic core, the requirements of working frequency and Q value should be mainly considered. When the general working frequency is below 1MHz, the magnetic core made of manganese-zinc ferrite should be properly used; When the working frequency is higher than 1MHz, the magnetic core made of Ni-Zn-Fe-O material should be selected. Under the condition of high Q value and low working frequency, a larger size spool should

Product picture

Company details

Company advantage

Transportation

FAQ