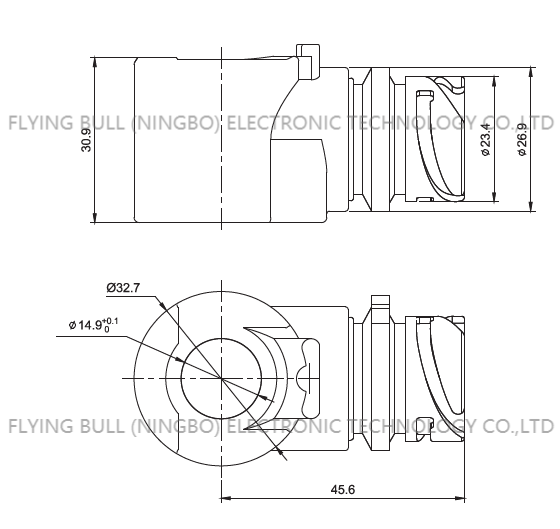

Automobile exhaust gas treatment solenoid valve coil FN15302

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Product name: Solenoid coil

Normal Voltage: DC24V DC12V

Normal Power (DC): 9W 12W 12W

Insulation Class: H

Connection Type: Plug-in type

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB789

Product Type: FXY15302

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Cause analysis and maintenance method of inductance coil burning out

There are many reasons for the burning of inductance coil, and we can consider the prevention from the following factors:

1. The design margin of inductance coil is not enough; In order to save the cost, the manufacturer did not leave some room. The design margin was originally a part of the product that was deliberately designed in consideration of various factors that the product would encounter during the design process.

2. The quality problem of enameled wire; In order to reduce the production cost, manufacturers use enameled wires with temperature resistance below 130℃~150℃.

3. Temperature rise of the inductor coil; Generally speaking, the design requirement of the inductor coil is below 60K, and the heat resistance of the polyester enameled wire should reach 155℃. Some designers cut the number of turns of the inductor coil to reduce the cost and raise the temperature of the inductor coil to 75K~90K, which makes the inductor enameled wire work at high temperature for a long time. Once it is overloaded for a long time, it may cause poor contact of the conductive parts and increase the contact resistance, which will greatly reduce the insulation strength of the inductor coil.

4. The counterforce coordination between the suction forces of the inductor coil; When the voltage is low, the pull-in will become difficult, the action time of the inductance coil will be long, and the time for the inductance coil to bear the strong starting current will be longer, which will make the inductance coil heat up, and at the same time make the suction force more obviously lacking, making the pull-in more difficult until it cannot be pulled in. The inductance coil works at high temperature, which leads to an increase in resistance and a very large current.

5. The working voltage range of the product design is not wide enough. Once the voltage is 80%~85%, it is possible that it cannot be attracted in hot state. When the voltage is higher than 120%, the inductance coil is easy to overheat.

The inductance coil is burnt due to the above reasons, and it can be used continuously as long as it is repaired simply. The way is to rewind the coil. As long as the short circuit turns are not particularly large, the short circuit is at the end of the coil, and the rest of the inductor coils are intact, then the damaged parts can be removed and the rest can be used continuously, which has little influence on the working performance of some inductors.

In fact, some accidents of burnt-out inductance coils can be completely avoided, and some accidents can be effectively eliminated in the bud as long as they are operated according to production requirements and strict quality requirements.

Product picture

Company details

Company advantage

Transportation

FAQ