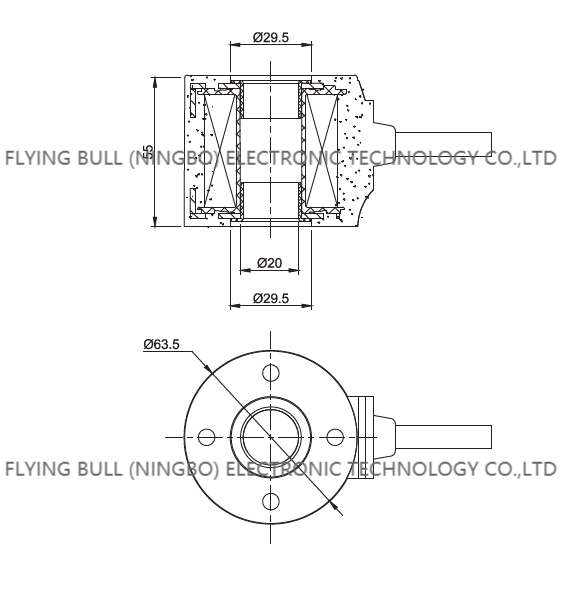

Two-position two-way waterproof solenoid valve coil FN20551

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Product name: Solenoid coil

Normal Voltage: AC220V AC110V DC24V DC12V

Normal Power (AC): 28VA

Normal Power (DC): 30W 38W

Insulation Class: F, H

Connection Type: Lead type

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB558

Product Type: 20551

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Principle and manufacturing method of solenoid valve coil

1. By creating an electromagnetic coil around the wire, winding the electromagnetic coil into a spiral shape will turn it into an enhanced magnetic field, which is to make the intensity of the magnetic field larger in a smaller space. Wrapping a wire with insulating paint on the outer surface of the electromagnetic coil can save space, and the molding function of light alloy is effectively improved by electromagnetic molding. The structure of the coil is one of the key factors for the left and right molding quality. The distribution of electromagnetic force is determined according to the deformed part of the workpiece, and the corresponding electromagnetic coil is designed accordingly.

2. Determine the direction of the magnetic field of the electromagnetic coil according to the "Right-hand Spiral Rule", also known as the "Ampere Rule". Hold the electrified solenoid with the right hand, so that the four fingers are twisted in the same direction as the current direction. The end pointed by the thumb is the N pole of the electrified solenoid, and the right hand holds the electrified straight conductor, so that the thumb points to the current direction. Then the direction pointed by the four fingers is the direction where the magnetic induction line is coiled, and opposites attract each other. Each coil of the energized solenoid will produce magnetism, and all the magnetism they produce will be superimposed to form the shape of a magnetic field. Therefore, it can be seen that the shape of the magnetic force generated by the energized solenoid and a magnet is similar, and the magnetic field inside the solenoid and the external magnetic field combine to form a closed magnetic field line.

3. There are many winding methods for electromagnetic coils, which can be divided into flat coil, circular straight coil and U-shaped winding method according to the shapes of different heaters. When winding, they can be closely next to each other until the winding is finished. This dense winding method is selected when the length of the barrel is limited, and it is usually not selected when the barrel is long enough, because the heating hands of this winding method are gathered in contrast (the heating hands are gathered in the center of the wound coil) Therefore, in the case of a certain length of the barrel, in order to make the hot hand evenly scattered on the barrel, Xiaobian usually suggests to choose another winding method, such as winding the coil round by round for four or five times or five or six times, then blocking six or seven centimeters and then winding it in several sections.

4. Because the electromagnetic induction coil should resist high temperature, it is necessary to use temperature-resistant data to wind it. In order to get used to the normal operation of the electromagnet at high temperature, it is necessary to choose high-quality ferrite for double-layer heating, and the heat conversion effect will be greatly improved to more than 99%.

Product picture

Company details

Company advantage

Transportation

FAQ