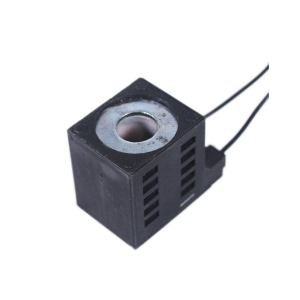

SV10-24 solenoid valve threaded cartridge valve reversing valve

Details

Sealing material:Direct machining of valve body

Pressure environment:ordinary pressure

Temperature environment:one

Optional accessories:valve body

Type of drive:power-driven

Applicable medium:petroleum products

Points for attention

Advantages of hydraulic system cartridge valves

Because the cartridge logic valve has been standardized at home and abroad, whether it is the international standard ISO, German DIN 24342 and our country (GB 2877 standard) have stipulated the world's common installation size, which can make the cartridge parts of different manufacturers can be interchangeable, and does not involve the internal structure of the valve, which also gives the design of the hydraulic valve has broad room for development.

The cartridge logic valve is easy to integrate: multiple components can be concentrated in a block body to form a hydraulic logic control system, which can reduce the weight of the system composed of conventional pressure, direction and flow valves by 1/3 to 1/4, and the efficiency can be increased by 2% to 4%.

Fast reaction speed: Because the cartridge valve is a seat valve structure, the spool starts to pass oil as soon as it leaves the seat. On the contrary, the slide valve structure must finish the covering amount before starting to connect the oil circuit, and the time to complete the pressure relief of the control chamber and open the cartridge valve is only about 10ms, and the reaction speed is fast.

Solenoid valve Overview

Solenoid valve is an industrial equipment controlled by electromagnetic, is used to control the basic components of fluid automation, belongs to the actuator, is not limited to hydraulic, pneumatic. Used in industrial control systems to adjust the direction of media, flow, speed and other parameters. The solenoid valve can be combined with different circuits to achieve the desired control, and the precision and flexibility of the control can be guaranteed. There are many kinds of solenoid valves, different solenoid valves play a role in different positions of the control system, the most commonly used are check valves, safety valves, direction control valves, speed regulating valves and so on.

Solenoid valve has a closed chamber, open a hole in different positions, each hole is connected to a different tubing, the middle of the cavity is a piston, two sides are two electromagnets, which side of the magnet coil energized valve body will be attracted to which side, by controlling the movement of the valve body to open or close different oil discharge holes, and the oil inlet hole is usually open, hydraulic oil will enter a different oil discharge pipe, Then through the pressure of the oil to push the piston of the cylinder, the piston in turn drives the piston rod, the piston rod drives the mechanical device. In this way, mechanical motion is controlled by controlling the current of the electromagnet.

Product specification

Company details

Company advantage

Transportation

FAQ