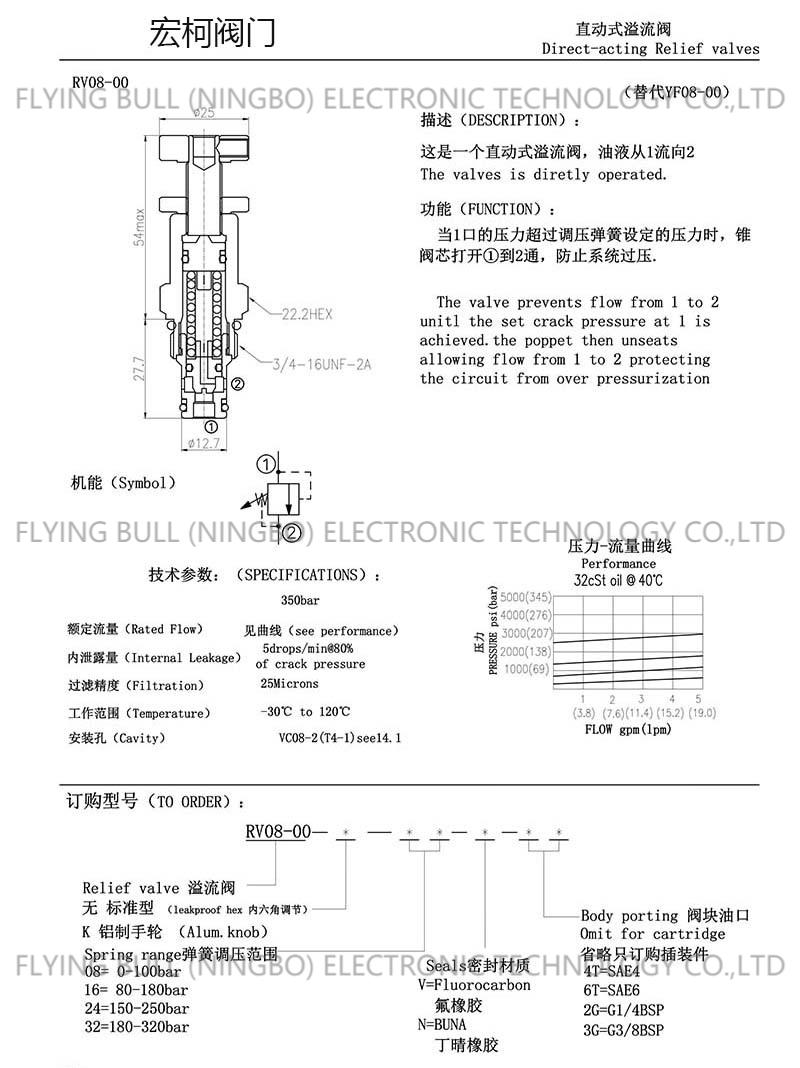

Pressure regulating safety oil pressure valve YF08-00

Details

Sealing material:rubber

Temperature environment:normal atmospheric temperature

Optional accessories:hand shan

Applicable industries:machinery

Type of drive:electromagnetism

Applicable medium:petroleum products

Points for attention

Oil pressure valve, also known as process valve, belongs to fully open and fully closed valve, which requires to be opened through and closed tightly. Its function is to switch gas, move towards the conversion connection in the realization stage, and form circulating gas production.

The oil pressure network of the gas-making system is the central nerve of gas-making. It strictly carries out the signal instructions sent by the microcomputer and transmits power to drive the oil pressure valve to switch the gas flow direction to complete the circulation work. As the actuator, the hydraulic valve has the following characteristics: the accuracy of opening and closing in place, the tightness of closing, the utilization rate of opening path, the speed of opening and closing in place, and the reliability and operating efficiency. It directly affects the safety and efficiency of gas stove operation. To ensure and improve the performance and quality of hydraulic valves, it is required to improve the design, manufacture and material selection of valves.

With the improvement of continuous operation capacity of gas stoves, new production characteristics have put forward higher requirements for the performance and quality of valves. Therefore, every manufacturer should pay more attention to the performance and quality of oil pressure valves. In the past, people only paid attention to whether the valve could be tightly closed and its service life.

Nowadays, gate valves are still widely used in the gas generation system of small nitrogen fertilizer industry. Blow valve is the most widely used position. Nearly 70% of single furnace systems use a gate valve and a hydraulic butterfly valve as a valve group for the inlet air valve position. Because the gate valve is connected in a straight line on the air duct, there will be no bending angle due to the installation of the valve, and the blowing resistance should not be generated. However, is the blowing resistance small? The original design of the gate valve has two shortcomings. First, the internal parts are complicated and easy to fall off, with high failure rate and high maintenance cost. Second, the stroke of the ram is not enough. When it is opened, 20%-25% of the ram hangs at the valve port, so it cannot be lifted up to produce resistance.

Product specification

Company details

Company advantage

Transportation

FAQ