Hydraulic threaded cartridge valve control RV10/12-22AB

Details

Valve action:regulate pressure

Type (channel location):Direct acting type

Lining material:alloy steel

Sealing material:rubber

Temperature environment:normal atmospheric temperature

Applicable industries:machinery

Type of drive:electromagnetism

Applicable medium:petroleum products

Points for attention

First, the reasons for the failure of relief valve pressure regulation

1. The pre-tightening force of the spring has not reached the adjustment function, which makes the spring lose its elasticity.

2. The coil in the differential pressure relay is burnt out or has poor contact.

3. The pointer of the pressure gauge is deviated, resulting in inaccurate pressure.

4, pressure regulating valve spring deformation or fracture and other faults.

Second, the relief valve pressure regulation failure solution

1. The pre-tightening force of the spring should be readjusted when regulating the pressure. According to the actual situation, the handwheel can be turned to the end when the spring is compressed for at least 10-15 mm. If the pressure rises, the pre-tightening force is too small, and it needs to be re-adjusted.

2. If the pressure does not meet the rated requirements, the overflow relief valve can be adjusted until it reaches the specified value. The third is to adjust the deformation or breakage of the spring, so it can only be adjusted by replacing a new spring.

The failure of relief valve regulation will have a great impact, especially when the equipment is in a high load state. When the relief valve is found to be out of order, the first step to be taken is to lower the pressure and then debug it again, so that it can resume normal work after several more times.

1. Check whether the throttle device leaks oil: if there is leakage, it may be that the sealing ring between the valve core and the valve seat of the throttle valve is damaged, resulting in poor sealing.

2. Check the impurities on the sealing surface of the throttle: If impurities jam the spring or make the valve core hit the sealing surface of the valve seat during throttling, it will also cause throttling failure.

3. Check the surface roughness of the throttle: When the surface roughness of the throttle does not meet the standard requirements, it is easy to reduce the cross-sectional area of the channel, reduce the flow rate and cause blockage.

4. When the one-way throttle valve fails to adjust the flow, the throttle piece should be ground first.

5. Check whether the installation position of the one-way throttle valve is correct. If it is not correct, re-calculate the hydraulic working condition and determine the flow resistance coefficient. After re-calculating the hydraulic working condition and hydraulic balance, determine its pressure level according to the calculation results and select the appropriate throttle valve model.

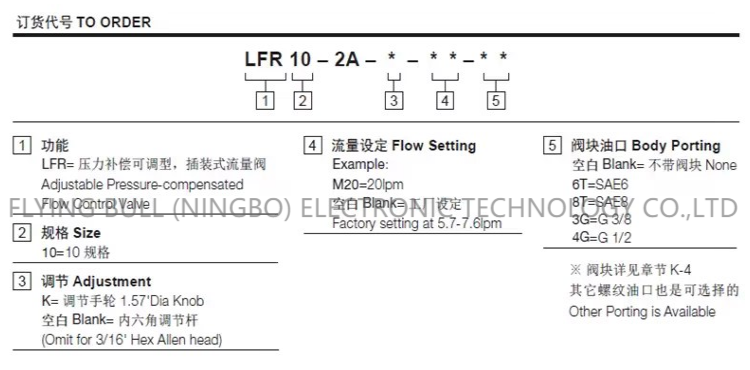

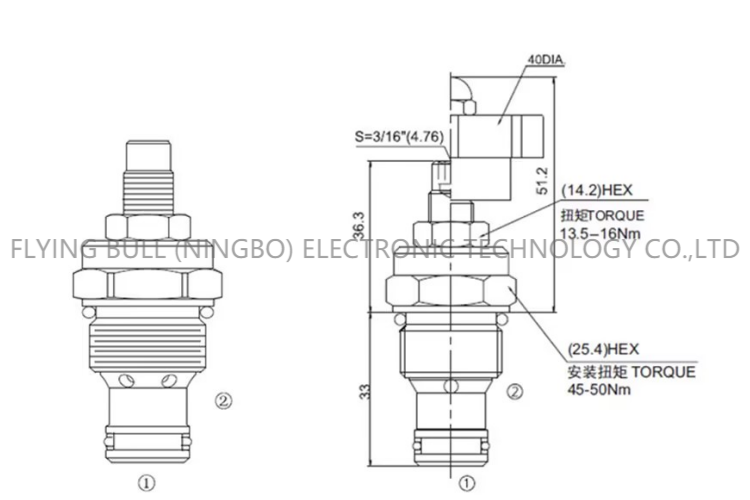

Product specification

Company details

Company advantage

Transportation

FAQ