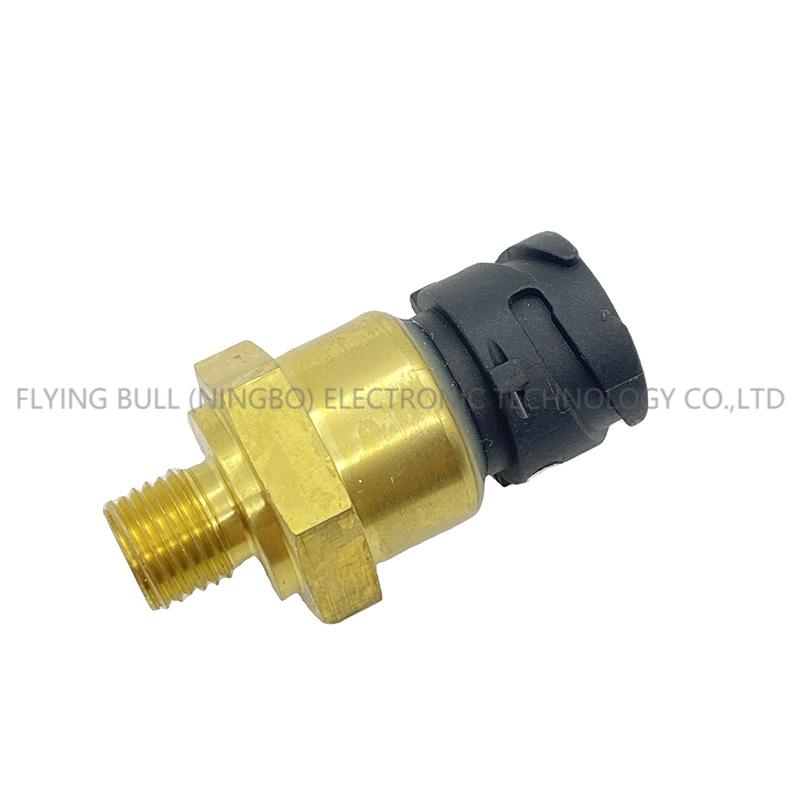

Oil pressure sensor for Volvo heavy truck parts 15047336

Product introduction

PPM-241A also collects weight signals by measuring oil pressure, and uses digital circuits to process sensor signals according to customers' specific requirements.

1. Features of this product:

A, the signal is large and easy to convert.

B, high precision and good stability.

C, good anti-vibration, impact, overload ability.

D, strong anti-interference ability.

E, corrosion resistance, high temperature resistance, small temperature drift.

When the loader weighs the goods, the oil pump connected to the bucket is constantly moving, and the temperature of the oil (medium to be measured) in the oil pump will rise after repeated high pressure. The temperature factor is fully considered in the selection of the strain gauge for the PPM-242L sensor, and corresponding measures are taken to make the temperature drift of the sensor as small as possible, < ±0.03%FS. Generally, it is installed through the pressure pipe during installation. In this way, the temperature and impact borne by the sensor are relieved, thus increasing the use stability of the equipment.

1), PPM-242L main features:

A, high precision, good long-term stability.

B, well sealed and corrosion-resistant.

C, low cost and high cost performance.

To sum up, according to the experience accumulated in the production process and the situation reflected by customers, it is said that we do not recommend the use of heavy-duty sensors. Among the oil pressure sensors, PPM-242L is an economical sensor, while PPM-216A sensor and PPM-241A transmitter are two very good sensors in terms of performance and installation difficulty. Among them, PPM-241A transmitter has low requirements for subsequent signal processing and instrument display, and is easier to use.

(1) Installation location

Description:

On the hydraulic circuit of the left and right support arm cylinders, one on each side.

Installation method:

1. Installation through oil passage adapter block 2. Installation and connection can also be made through pressure pipe.

(2), installation considerations

1) The thread installation shall be sealed, and auxiliary appliances such as sealant or raw material belt shall be adopted during installation;

2), wiring in strict accordance with the product manual, to prevent product damage caused by misoperation;

3) During calibration, multi-parameter tests should be carried out for different directions and angles to ensure that the weighing accuracy of the equipment is consistent in various states;

4), such as space constraints can't be normal installation, should consider using the way of lead-out pressure pipe installation, after debugging is completed, then fixed.

Product picture

Company details

Company advantage

Transportation

FAQ