Energy efficiency has become a critical focus for manufacturing industries in 2024. Several factors drive this shift: investments in energy efficiency are projected to grow by 4%, reaching $660 billion, and nearly 10 million jobs now support this sector. Energy-efficient solenoid valves offer a transformative solution. These advanced devices reduce energy consumption by up to 80%, significantly lowering operational costs while supporting sustainability goals.

Key Takeaways

- Energy-saving solenoid valves use up to 80% less energy. This helps factories save a lot of money.

- These valves work better and last longer. They need less fixing and stay dependable for a long time.

- Using energy-saving solenoid valves helps factories follow energy rules. It also supports worldwide eco-friendly goals.

What Are Energy-Efficient Solenoid Valves?

Definition and Functionality

Energy-efficient solenoid valves are advanced devices designed to control the flow of liquids or gases while minimizing energy consumption. These valves operate using an electromagnetic coil that activates a plunger to open or close the valve. Unlike traditional solenoid valves, energy-efficient models incorporate innovative technologies such as low-power circuits and latching mechanisms. These features reduce the energy required to maintain the valve’s position, making them ideal for applications where efficiency is critical.

Key technical specifications define their performance. For example:

| Specification Type | Description |

|---|---|

| Flow Rates | Maximum and minimum flow rates affected by pipe size and pressure drop. |

| Flow Coefficient (Cv) | Measures the flow capacity; should meet or exceed designed flow rates. |

| Pressure and Temperature Variations | Each valve operates within specific ranges; must satisfy system conditions. |

| Valve Designs | Includes normally open/closed and directly/indirectly operated valves influencing energy use. |

| Cycling Requirements | Frequency and duration of valve operation affect energy efficiency. |

| Size of Solenoid Valve | Larger valves draw more energy; oversized valves can lead to unnecessary energy consumption. |

Differences from Traditional Solenoid Valves

Energy-efficient solenoid valves differ significantly from traditional models in their operational mechanisms and energy requirements. Traditional AC solenoid valves require a strong peak current to open but consume less energy to stay open. In contrast, DC solenoid valves demand a constant current, leading to higher energy use. Energy-efficient designs, such as latching solenoid valves, use a permanent magnet to hold the valve in position, eliminating the need for continuous power. These innovations reduce energy consumption by up to 95% after activation, offering substantial cost savings.

Importance in Modern Manufacturing

Modern manufacturing relies on energy-efficient solenoid valves to optimize processes and reduce operational costs. These valves save energy by operating at as little as 0.5 watts, which can translate into millions of dollars in savings for facilities using multiple valves. Additionally, they help industries meet stringent energy regulations and sustainability goals. By reducing energy consumption, these valves not only lower costs but also enhance environmental responsibility, appealing to eco-conscious stakeholders.

Benefits for Manufacturing Plants

Energy Savings and Cost Reduction

Energy-efficient solenoid valves offer substantial energy savings, which directly translate into cost reductions for manufacturing plants. These valves utilize advanced technologies, such as Kick and Drop mechanisms, to reduce energy consumption by up to 80%. This efficiency leads to significant operational cost savings, with some facilities reporting thousands of euros saved annually. A study by the SBIR Project highlights that these valves can achieve energy savings of 20-25%, potentially resulting in national savings of $400 to $500 million for U.S. manufacturers.

| Source | Energy Savings Percentage | Cost Reduction Implication |

|---|---|---|

| SBIR Project | 20-25% | Significant savings on energy bills, potential national savings of $400 to $500 million. |

| Kick and Drop Technology | Up to 80% | Lower energy consumption leads to significant reductions in operating costs. |

Enhanced Performance and Durability

Energy-efficient solenoid valves are designed to deliver superior performance and durability. Their optimized designs minimize energy waste while ensuring reliable operation in demanding environments. Key metrics supporting their enhanced performance include energy consumption, peak current requirements, and cycling capabilities. For instance:

- Energy Consumption: Advanced designs reduce power usage during operation.

- Cycling Requirements: Frequent and prolonged use does not compromise durability.

- Design Variations: Tailored designs improve fluid control efficiency.

These features ensure that the valves maintain consistent performance over time, reducing the need for frequent replacements and lowering maintenance costs.

Contribution to Sustainability Goals

By reducing energy consumption, energy-efficient solenoid valves contribute significantly to sustainability objectives. They help lower CO₂ emissions, aiding manufacturers in meeting corporate environmental goals and complying with energy regulations. For example, these valves can achieve up to 80% energy savings compared to traditional models, resulting in reduced environmental impact and rapid return on investment within 2-3 years. Even small energy savings per valve can lead to substantial reductions when scaled across multiple systems.

| Benefit | Description |

|---|---|

| Energy Savings | Up to 80% energy savings compared to traditional solenoid valves. |

| Reduced Operating Costs | Significant reduction in energy bills, potentially saving thousands of euros annually. |

| Lower Environmental Impact | Decrease in CO₂ emissions, aiding in corporate sustainability goals and compliance with regulations. |

| Rapid Return on Investment | Investment costs typically amortized within 2-3 years due to energy savings. |

By adopting energy-efficient solenoid valves, manufacturers can align with global sustainability trends while achieving cost and energy efficiencies.

Innovations Driving Efficiency

Low Power Consumption Technologies

Recent advancements in solenoid valve design have prioritized energy efficiency. Modern low-power solenoid-operated valves (SOVs) now consume as little as 0.55 watts, a significant improvement over traditional models. These valves incorporate larger orifices and standard filters, which enhance flow handling capabilities without increasing energy demands. By reducing power consumption, these innovations help manufacturing plants lower operational costs while maintaining high performance.

Additionally, the integration of Internet of Things (IoT) technology has revolutionized valve efficiency. IoT-enabled solenoid valves allow real-time monitoring and remote control, ensuring optimal energy use and reducing unnecessary power draw. This combination of low power consumption and smart technology makes these valves indispensable for energy-conscious manufacturers.

Kick and Drop Technology

Kick and Drop technology represents another breakthrough in solenoid valve efficiency. This mechanism uses a high initial current (the “kick”) to activate the valve, followed by a significantly reduced holding current (the “drop”) to maintain its position. By minimizing energy use during operation, this technology reduces power consumption by up to 80%.

Manufacturers benefit from this innovation through lower energy bills and extended valve lifespan. The reduced heat generation during operation also decreases wear and tear, ensuring consistent performance over time. Kick and Drop technology exemplifies how small design changes can lead to substantial energy savings.

Compact and Versatile Designs

Modern energy-efficient solenoid valves feature compact and versatile designs, making them ideal for space-constrained applications. Miniaturization has enabled these valves to fit into smaller systems without compromising performance. Despite their reduced size, they maintain high flow rates and pressure handling capabilities, ensuring reliable operation across various industries.

These compact designs also enhance system flexibility. Manufacturers can integrate them into existing setups with minimal modifications, reducing installation costs. Combined with their energy-saving features, these versatile valves provide a cost-effective solution for diverse industrial needs.

Applications Across Industries

HVAC and Climate Control Systems

Energy-efficient solenoid valves play a pivotal role in HVAC systems by ensuring precise control of fluid flow. These valves regulate refrigerant and water flow, optimizing energy use and maintaining consistent temperatures. Their advanced coil designs reduce power consumption, which lowers operational costs. Additionally, their rapid response times allow HVAC systems to adapt quickly to temperature changes, enhancing overall performance.

| Benefit | Description |

|---|---|

| Energy Efficiency | Coils are optimized to require less power, conserving energy and reducing operational costs. |

| Reduced Energy Consumption | Effective regulation of refrigerant flow leads to lower energy consumption and utility bills. |

| Quick Response Time | Rapid actuation allows for prompt adjustments to temperature fluctuations, optimizing performance. |

| Reduced Maintenance | Durable design requires minimal maintenance, decreasing downtime and operational costs. |

The growing demand for energy-efficient HVAC systems has further increased the adoption of these valves, making them indispensable in modern climate control applications.

Water and Fluid Management

In water and fluid management systems, energy-efficient solenoid valves ensure precise control over liquid distribution and treatment processes. These valves maintain system integrity by regulating flow rates and pressure levels. Their compact designs and low power requirements make them ideal for large-scale operations, such as municipal water treatment plants and industrial fluid systems.

| Sector | Application Description |

|---|---|

| Water and Wastewater | Critical role in controlling water distribution, treatment processes, and maintaining system integrity. |

By reducing energy consumption, these valves contribute to cost savings and environmental sustainability, aligning with the goals of water management industries.

Gas and Safety Systems

Gas and safety systems rely on energy-efficient solenoid valves for accurate and reliable control of gas flow. These valves are critical in applications such as gas detection, emergency shut-off systems, and industrial safety mechanisms. Their ability to operate with minimal power ensures uninterrupted performance during emergencies, enhancing safety and reducing energy costs.

The automotive sector also benefits from these valves in fuel injection and emission control systems. By ensuring efficient gas flow, they help vehicles comply with stringent environmental regulations while improving fuel efficiency.

| Sector | Application Description |

|---|---|

| Automotive | Integral in fuel injection and emission control systems, ensuring efficient operation and compliance. |

Energy-efficient solenoid valves provide a versatile solution for industries requiring precise gas control, ensuring both safety and efficiency.

Financial Impact and ROI

Rapid Payback Period

Energy-efficient solenoid valves offer a rapid return on investment (ROI), making them a financially sound choice for manufacturing plants. Although their initial cost is higher than traditional valves, the energy savings they provide quickly offset this expense. For example, facilities that replace outdated valves with energy-efficient models often report a payback period of less than two years. This quick recovery stems from reduced energy consumption, which lowers utility bills significantly. Additionally, the enhanced durability of these valves minimizes the need for frequent replacements, further accelerating ROI.

Long-Term Maintenance Savings

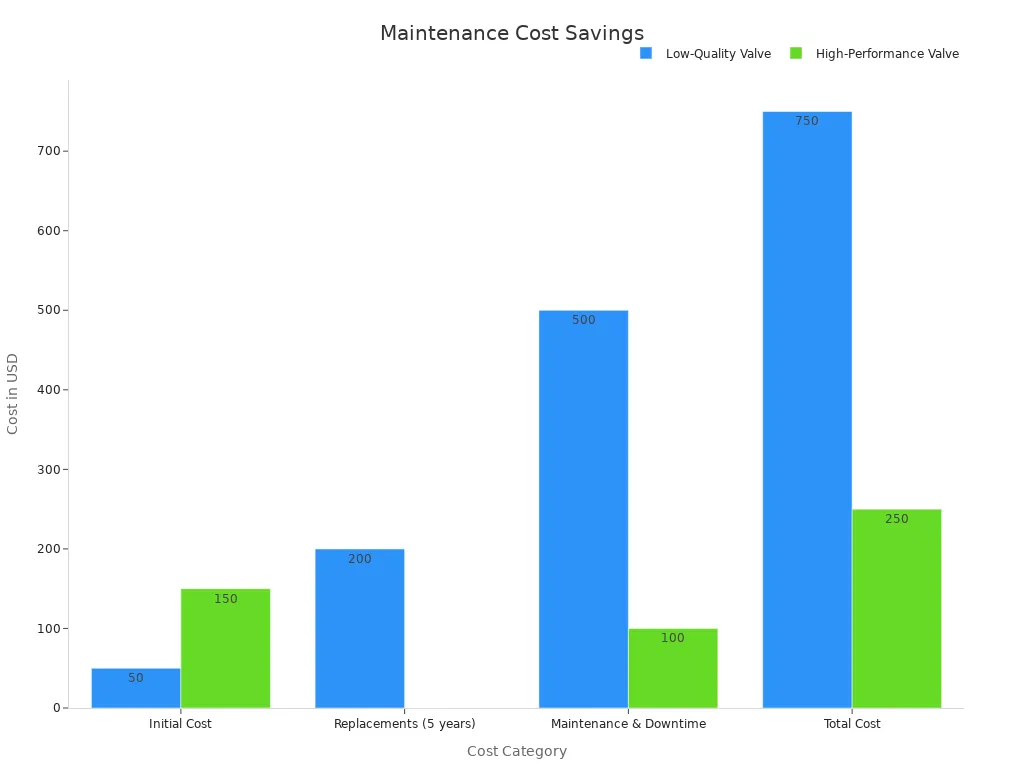

The long-term maintenance savings associated with energy-efficient solenoid valves are substantial. High-performance valves, built with durable materials, reduce the frequency of replacements and maintenance interventions. A cost comparison highlights this advantage:

| Category | Low-Quality Valve | High-Performance Valve |

|---|---|---|

| Initial Cost | $50 | $150 |

| Replacements (5 years) | $200 | $0 |

| Maintenance & Downtime | $500 | $100 |

| Total Cost | $750 | $250 |

Switching to high-performance valves saves $500 over five years while reducing operational disruptions. The chart below further illustrates this cost efficiency:

Overall Cost Efficiency

Energy-efficient solenoid valves deliver comprehensive cost efficiency by combining energy savings, reduced maintenance, and enhanced operational reliability. Their durable construction lowers replacement costs, while energy-efficient coils reduce power consumption. Improved flow precision minimizes unplanned downtime, ensuring smooth operations. A customer case study revealed a 25% annual reduction in maintenance costs after switching to premium solenoid valves. Although the upfront cost is higher, the extended lifespan and reliability of these valves provide superior long-term value.

| Benefit | Description |

|---|---|

| Long-Term Cost Savings | Durable materials reduce replacements; energy-efficient coils lower costs. |

| Enhanced Operational Efficiency | High-quality valves improve flow precision and reduce downtime. |

| Better ROI | Higher initial costs yield better returns over time. |

By adopting energy-efficient solenoid valves, manufacturers can achieve significant cost savings while enhancing system performance and reliability.

Preparing for the Future

Compliance with Energy Regulations

Energy regulations are shaping the future of industrial operations, particularly in the adoption of energy-efficient solenoid valves. These regulations mandate lower power consumption and encourage innovative designs to meet environmental standards. For instance:

- The EU’s Ecodesign Directive (ErP Lot 30) requires solenoids to reduce standby power consumption below 0.5 watts by 2025.

- Manufacturers are adopting latching solenoid designs, which reduce power use by up to 70%.

- Regulatory frameworks promote energy efficiency, driving innovation in valve design and performance.

| Regulation | Description |

|---|---|

| EU Ecodesign Directive (ErP Lot 30) | Mandates solenoids in appliances reduce standby power consumption below 0.5 watts by 2025. |

| Energy Efficiency Innovations | Encourages manufacturers to adopt latching solenoid designs that reduce power use by up to 70%. |

By complying with these standards, manufacturers can avoid penalties, enhance operational efficiency, and contribute to global sustainability efforts.

Staying Competitive in 2024 and Beyond

The growing demand for automation and energy-efficient solutions is transforming industrial landscapes. The global solenoid valve market is expanding rapidly, driven by advancements in material science and the increasing focus on sustainability. Industries such as water management, automotive, and oil and gas are adopting energy-efficient solenoid valves to enhance productivity and operational efficiency.

The integration of IoT and AI technologies further strengthens the competitiveness of these valves. Real-time monitoring and predictive maintenance capabilities improve responsiveness to industrial needs. As regulatory standards tighten and sustainability becomes a priority, adopting energy-efficient solenoid valves ensures manufacturers remain competitive in a rapidly evolving market.

Aligning with Global Sustainability Trends

Energy-efficient solenoid valves align with global sustainability objectives by minimizing environmental impact. These valves optimize fluid and air flow, conserving resources and reducing waste. Key trends include:

- Use of Recycled Materials: Supporting resource conservation during production.

- Energy-Efficient Coils: Consuming less power to reduce energy usage.

- Renewable Energy Integration: Factories increasingly use solar and wind energy to lower carbon emissions.

Additionally, precision casting and additive manufacturing reduce material waste, while biodegradable packaging minimizes environmental impact during distribution. These practices highlight how energy-efficient solenoid valves contribute to a greener future.

Energy-efficient solenoid valves offer transformative benefits for manufacturing plants. They significantly reduce costs, enhance performance, and support sustainability goals. For example:

| Benefit | Description |

|---|---|

| Significant reduction in costs | Energy-efficient solenoid valves can save thousands of euros annually on energy bills. |

| Lower environmental impact | Reduced energy consumption leads to decreased CO₂ emissions, aiding sustainability goals. |

| Rapid return on investment | Investment costs are typically recovered within 2-3 years due to energy savings. |

| Superior performance | Higher switching pressure and reduced surface temperature enhance operational flexibility and safety. |

| Compact design | Space savings of up to 35% allow for greater installation flexibility. |

Adopting these technologies in 2024 ensures compliance with energy regulations, improves operational efficiency, and builds trust with stakeholders. Long-lasting components also reduce waste and maintenance costs, making them a smart investment for long-term success. Manufacturers should prioritize these solutions to remain competitive and align with global sustainability trends.

FAQ

What makes energy-efficient solenoid valves different from traditional valves?

Energy-efficient solenoid valves use advanced technologies like latching mechanisms and low-power circuits. These features reduce energy consumption by up to 80%, offering significant cost savings and improved sustainability.

How long does it take to see a return on investment (ROI)?

Most manufacturers report an ROI within 2-3 years. Energy savings, reduced maintenance costs, and enhanced durability contribute to the rapid payback period.

Post time: Mar-25-2025