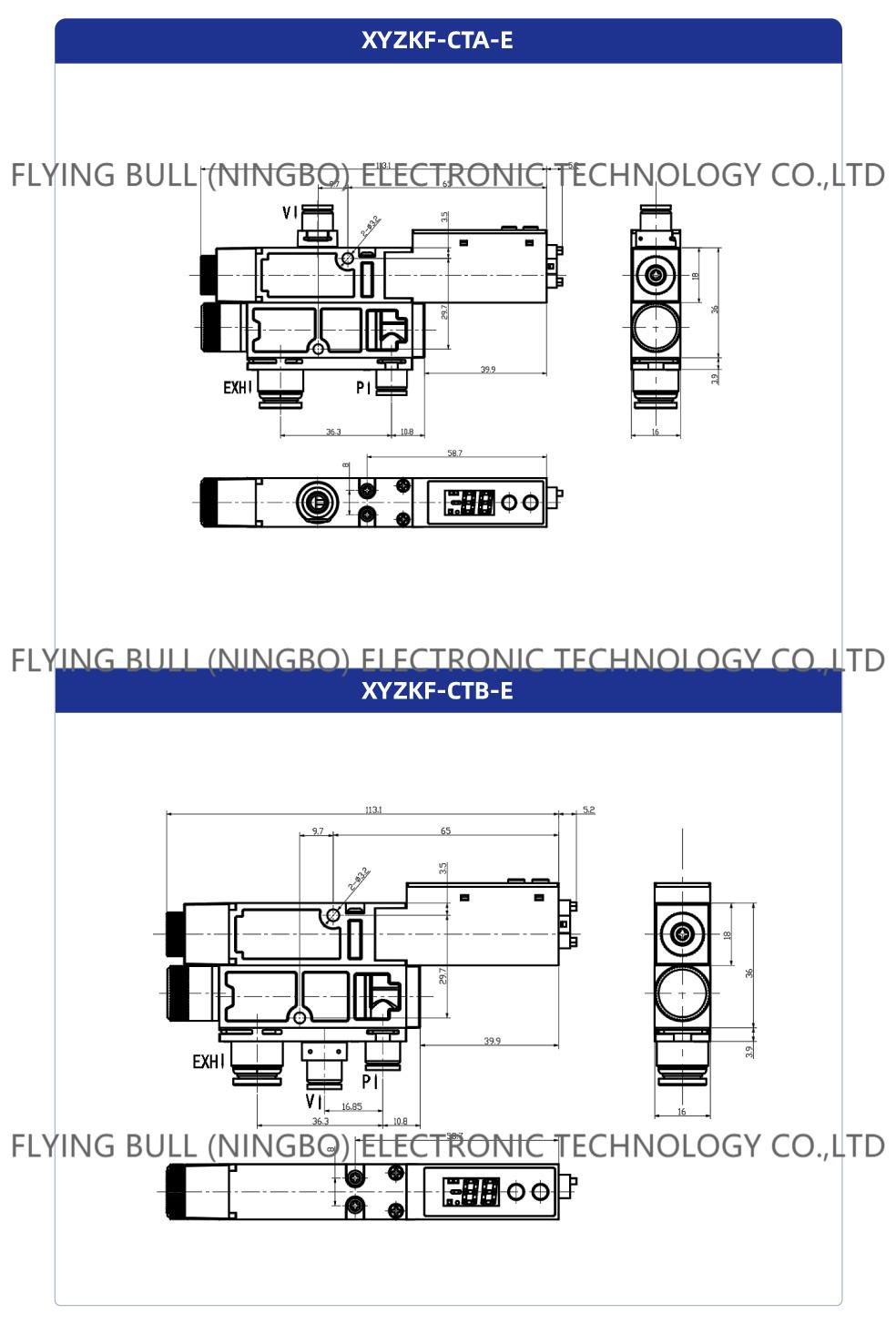

Single chip vacuum generator CTA(B)-E with two measuring ports

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Condition: New

Model Number: CTA(B)-E

Working medium: Compressed air

Electric current: <30mA

Part name: pneumatic valve

Voltage: DC12-24V10%

Working temperature: 5-50℃

Working pressure: 0.2-0.7MPa

Filtration degree: 10um

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

The vacuum generator is a new, efficient, clean, economical and small vacuum component that uses positive pressure air source to generate negative pressure, which makes it very easy and convenient to obtain negative pressure where there is compressed air or where both positive and negative pressure are needed in a pneumatic system. Vacuum generators are widely used in machinery, electronics, packaging, printing, plastics and robots in industrial automation.

The traditional use of vacuum generator is vacuum sucker cooperation to adsorb and transport various materials, especially suitable for adsorbing fragile, soft and thin non-ferrous and non-metallic materials or spherical objects. In this kind of application, a common feature is that the required air extraction is small, the vacuum degree is not high and it works intermittently. The author thinks that the analysis and research on the pumping mechanism of vacuum generator and the factors affecting its working performance are of practical significance to the design and selection of positive and negative compressor circuits.

First, the working principle of vacuum generator

The working principle of the vacuum generator is to use the nozzle to spray compressed air at a high speed, form a jet at the nozzle outlet, and generate entrainment flow. Under the entrainment effect, the air around the nozzle outlet is continuously sucked away, so that the pressure in the adsorption cavity is reduced to below atmospheric pressure, and a certain degree of vacuum is formed.

According to fluid mechanics, the continuity equation of incompressible air gas (gas is advancing at low speed, which can be approximately considered as incompressible air)

A1v1= A2v2

Where A1, a2-the cross-sectional area of the pipeline, m2.

V1, V2-airflow velocity, m/s

From the above formula, it can be seen that the cross section increases and the flow velocity decreases; The cross section decreases and the flow velocity increases.

For horizontal pipelines, the Bernoulli ideal energy equation of incompressible air is

P1+1/2ρv12=P2+1/2ρv22

Where P1, P2-corresponding pressures at sections A1 and A2, Pa

V1, V2-corresponding velocity at sections A1 and A2, m/s

ρ-density of air, kg/m2

As can be seen from the above formula, the pressure decreases with the increase of flow rate, and P1>>P2 when v2>>v1. When v2 increases to a certain value, P2 will be less than one atmospheric pressure, that is, negative pressure will be generated. Therefore, negative pressure can be obtained by increasing the flow rate to generate suction.

Product picture

Company details

Company advantage

Transportation

FAQ