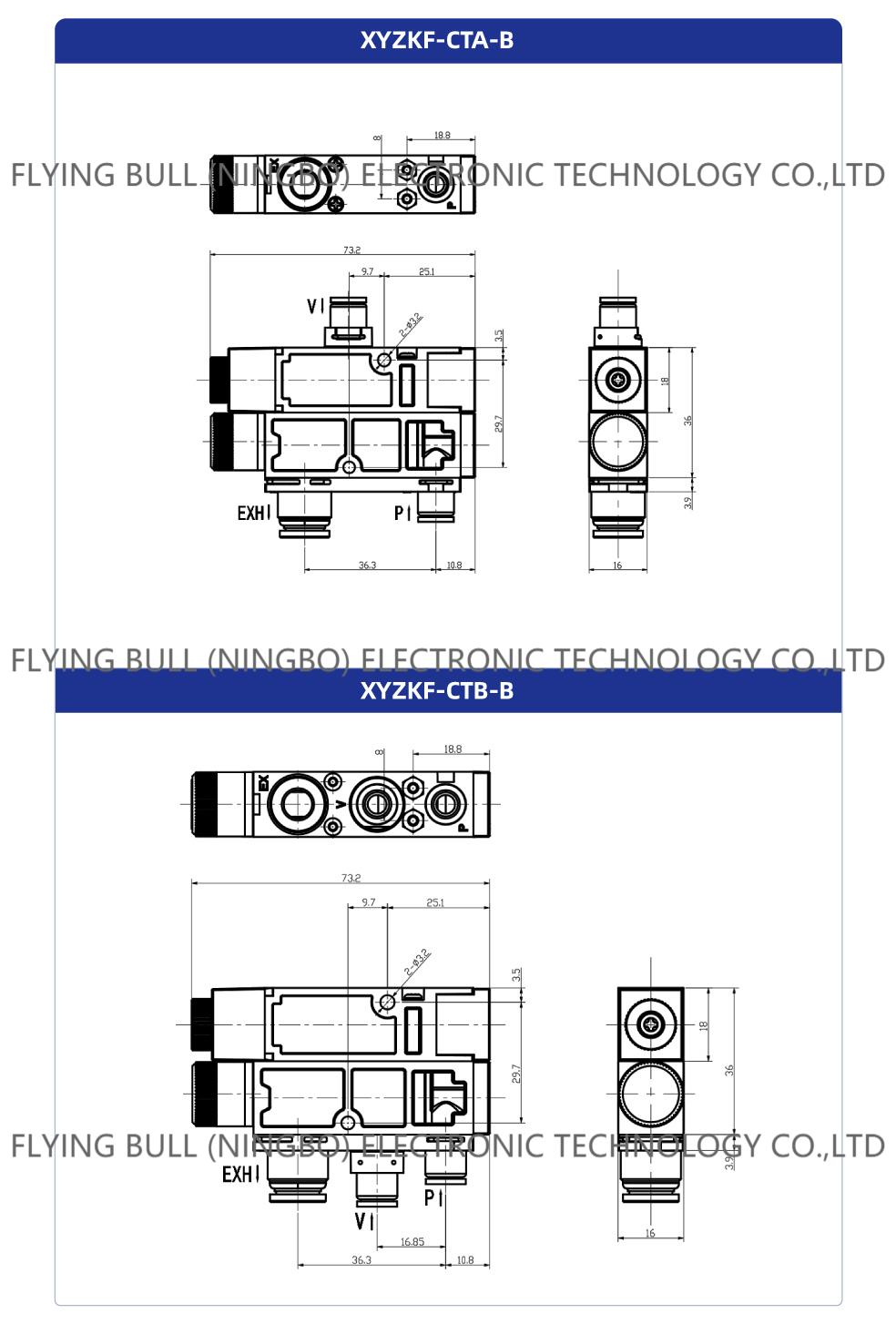

Single chip vacuum generator CTA(B)-B with two measuring ports

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Model Number: CTA(B)-B

The area of the filter: 1130mm2

Power-on mode: N.C.

Working medium: compressed air:

Part name: pneumatic valve

Working temperature: 5-50℃

Working pressure: 0.2-0.7MPa

Filtration degree: 10um

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Analysis of suction performance of vacuum generator

1. Main performance parameters of vacuum generator

① Air consumption: refers to the flow qv1 flowing out of the nozzle.

② Suction flow rate: refers to the air flow rate qv2 inhaled from the suction port. When the suction port is open to the atmosphere, its suction flow rate is the largest, which is called the maximum suction flow rate qv2max.

③ Pressure at the suction port: recorded as Pv. When the suction port is completely closed (e.g. the suction disc sucks the workpiece), that is, when the suction flow is zero, the pressure in the suction port is the lowest, recorded as Pvmin.

④ Suction response time: Suction response time is an important parameter indicating the working performance of vacuum generator, which refers to the time from the opening of reversing valve to reaching a necessary vacuum degree in the system loop.

2. Main factors affecting the performance of vacuum generator

The performance of vacuum generator is related to many factors, such as the minimum diameter of nozzle, the shape and diameter of contraction and diffusion tube, its corresponding position and the pressure of gas source. Fig. 2 is a graph showing the relationship among suction inlet pressure, suction flow rate, air consumption and supply pressure of a vacuum generator. It shows that when the supply pressure reaches a certain value, the suction inlet pressure is low, and then the suction flow rate reaches the maximum. When the supply pressure continues to increase, the suction inlet pressure increases, and then the suction flow rate decreases.

① Characteristic analysis of maximum suction flow qv2max: The ideal qv2max characteristic of vacuum generator requires that qv2max is at the maximum value within the range of common supply pressure (P01 = 0.4-0.5 MPa) and changes smoothly with P01.

(2) Characteristic analysis of the pressure Pv at the suction port: An ideal Pv characteristic of the vacuum generator requires that the Pv is at the minimum value within the range of common supply pressure (P01 = 0.4-0.5 MPa) and changes smoothly with Pv1.

(3) Under the condition that the suction inlet noise is completely closed, the relationship between the pressure Pv at the suction inlet and the suction flow rate under specific conditions is shown in Figure 3. In order to obtain an ideal matching relationship between the pressure at the suction inlet and the suction flow rate, multistage vacuum generators can be designed to be combined in series.

Product picture

Company details

Company advantage

Transportation

FAQ