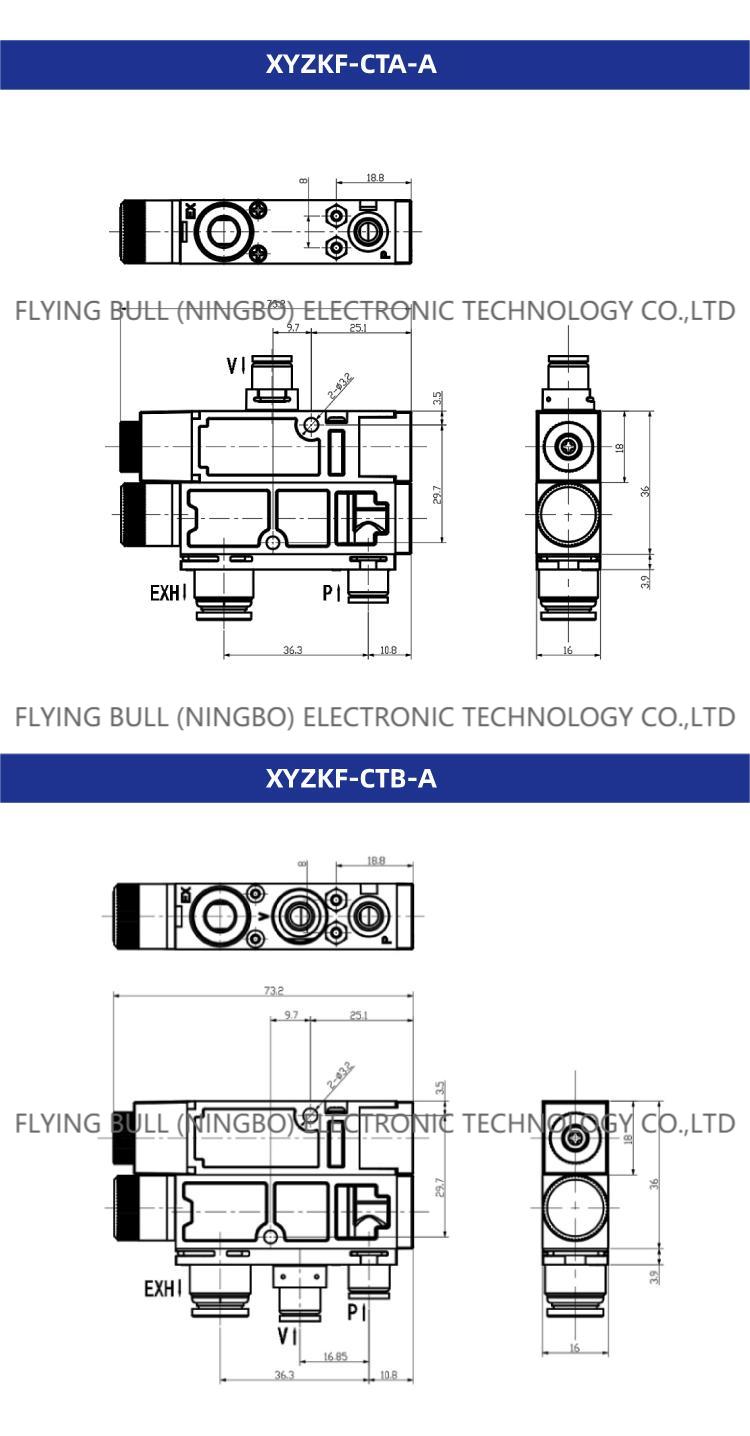

Single chip vacuum generator CTA(B)-A with two measuring ports

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

Condition: New

Model Number: CTA(B)-A

Working medium: Compressed air

Part name: Pneumatic valve

Working temperature: 5-50℃

Working pressure: 0.2-0.7MPa

Filtration degree: 10um

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Main factors affecting the performance of vacuum generator

1The length of the diffusion pipe should ensure the full development of various wave systems at the nozzle outlet, so that an approximately uniform flow can be obtained at the outlet section of the diffusion pipe. However, if the pipe is too long, the friction loss of the pipe wall will increase. It is reasonable for a general plumber to be 6-10 times the pipe diameter. In order to reduce the energy loss, an expansion section with an expansion angle of 6-8 can be added at the outlet of the straight pipe of the diffusion pipe.

2 The adsorption response time is related to the volume of the adsorption cavity (including the volume of diffusion cavity, adsorption pipeline, suction cup or closed chamber, etc.), and the leakage of the adsorption surface is related to the pressure at the required suction port. For a certain pressure requirement at the suction port, the smaller the volume of the adsorption cavity, the shorter the response time; If the pressure at the suction inlet is higher, the adsorption volume is smaller, the surface leakage is smaller, and the adsorption response time is shorter. If the adsorption volume is large and the adsorption speed is fast, the nozzle diameter of the vacuum generator should be larger.

3 The air consumption (L/min) of the vacuum generator should be reduced on the premise of meeting the use requirements. The air consumption is related to the supply pressure of compressed air. The greater the pressure, the greater the air consumption of the vacuum generator. Therefore, attention should be paid to the relationship between the supply pressure and air consumption when determining the pressure duty at the suction port. Generally, the pressure at the suction port generated by the vacuum generator is between 20kPa and 10kPa. At this time, if the pressure of the meter for supplying China increases again, the pressure at the suction port will not decrease, but the gas consumption will increase. Therefore, reducing the pressure at the suction port should be considered from the aspect of controlling the flow rate.

Product picture

Company details

Company advantage

Transportation

FAQ