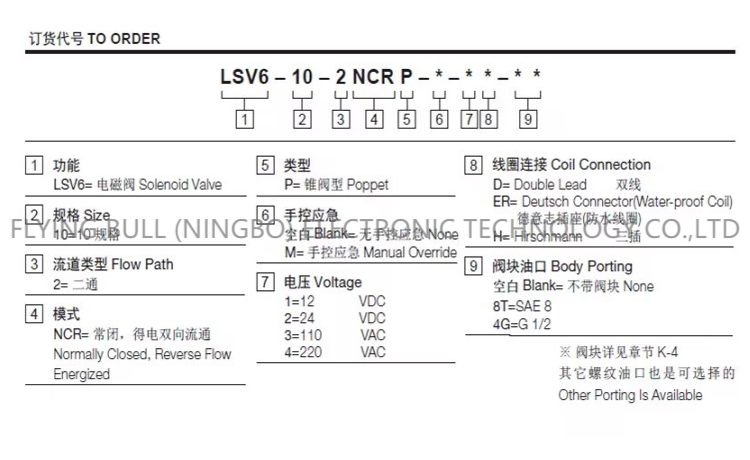

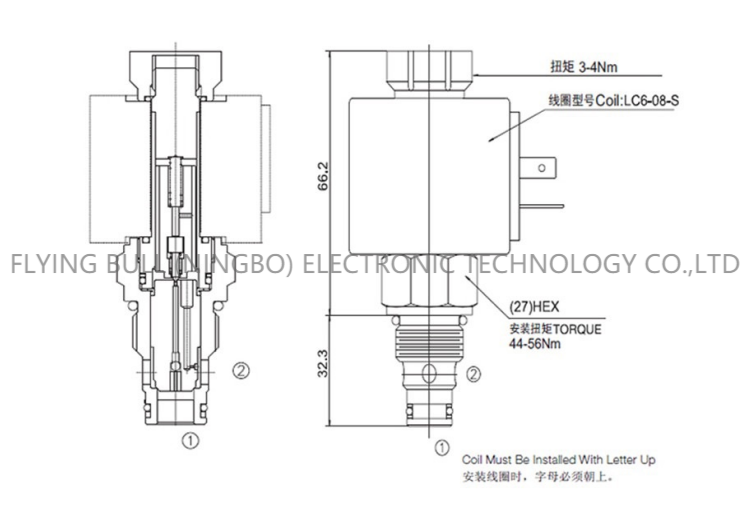

LSV6-10-2NCRP two-way check normally closed hydraulic cartridge valve

Details

Valve action:regulate pressure

Type (channel location):Direct acting type

Lining material:alloy steel

Sealing material:rubber

Temperature environment:normal atmospheric temperature

Applicable industries:machinery

Type of drive:electromagnetism

Applicable medium:petroleum products

Points for attention

Standard technical requirements for flow control valves

1 Pressure-temperature level

The pressure-temperature grade of flow control valve is determined by the pressure-temperature grade of shell, internals and control pipe system materials. The maximum allowable working pressure of the flow control valve at a certain temperature is the smaller of the maximum allowable working pressure values of the shell, internals and control pipe system materials at this temperature.

1.1 Pressure-temperature grade of iron shell shall comply with GB/T17241.7.

1.2 Pressure-temperature grade of steel shell shall comply with GB/T9124.

1.3 For materials whose pressure-temperature grade is not specified in GB/T17241.7 and GB/T9124, the relevant standards or design provisions can be followed.

2. Valve body

2.1 Valve body flange: The flange shall be integrally cast with the valve body. The type and size of the iron flange shall comply with GB/T17241.6, and the technical conditions shall comply with GB/T17241.7; The type and size of steel flange shall comply with GB/T9113.1, and the technical conditions shall comply with GB/T9124.

2.2 See Table 1 for the structural length of valve body.

2.3 Minimum wall thickness of valve body The minimum wall thickness of cast iron valve body shall comply with Table 3 in GB/T 13932-1992, and the minimum wall thickness of cast steel valve body shall comply with Table 1 in JB/T 8937-1999.

3 Valve cover diaphragm seat

3.1 The connection type between valve cover and diaphragm seat, diaphragm seat and valve body shall be flange type.

3.2 The number of connecting bolts between diaphragm seat and valve body shall not be less than 4.

3.3 The minimum wall thickness of valve cover and diaphragm seat shall meet the requirements of 2.3.

3.4 The flange of valve cover and diaphragm seat shall be round. Flange sealing surface can be flat, convex or concave-convex.

4. Valve stem, slow closing valve plate and main valve plate

4.1 Slow-closing valve plate and valve stem should be connected firmly and reliably.

4.2 The sealing type between the slow closing valve plate and the main valve plate should adopt the metal sealing type.

4.3 The main valve plate and valve stem must slide flexibly and reliably.

4.4 The seal between the main valve plate and the main valve plate seat can adopt two types: metal seal and nonmetal seal.

Product specification

Company details

Company advantage

Transportation

FAQ