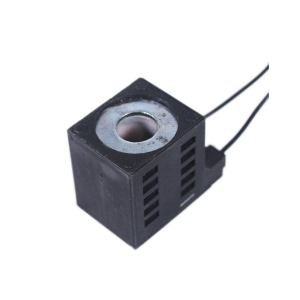

LSV5-08-2NCS Solenoid directional valve Hydraulic cartridge valve

Details

Sealing material:Direct machining of valve body

Pressure environment:ordinary pressure

Temperature environment:one

Flow direction:one-way

Optional accessories:valve body

Type of drive:power-driven

Applicable medium:petroleum products

Points for attention

Working principle of solenoid valve

Cartridge valves are sluice gates that operate fluids through hydraulic control and lever principles. It is composed of an electro-hydraulic mechanism, which is an electro-hydraulic linkage device that can convert the electrical signal received into a hydraulic output to achieve hydropower control.

The control signal of the cartridge valve is converted into a hydraulic output by the electro-hydraulic mechanism, so that the valve is constantly switched back and forth between closing and opening. The operation process of the cartridge valve is like this: when the valve is opened, the inside of the solenoid valve will emit a certain voltage, at this time, the internal magnetic force in the solenoid coil will produce the lever principle of the solenoid coil, which causes the movement of the internal shaft, and finally makes the pneumatic valve open Now the fluid flows. When the control signal changes, the above process undergoes a reverse change, which causes the valve to close and the fluid to be controlled.

The operation mode of cartridge valve is closely related, and the selection of cartridge valve should be based on the working condition characteristics and flow characteristics, comprehensive control parameters and so on. Cartridge valves have certain professional requirements and must be designed by professional engineers to ensure their quality and stability. Therefore, the installation and debugging of the cartridge valve is also more complicated, and the construction and debugging are carried out in strict accordance with the relevant regulations.

Advantages of hydraulic system cartridge valves

Because the cartridge logic valve has been standardized at home and abroad, whether it is the international standard ISO, German DIN 24342 and our country (GB 2877 standard) have stipulated the world's common installation size, which can make the cartridge parts of different manufacturers can be interchangeable, and does not involve the internal structure of the valve, which also gives the design of the hydraulic valve has broad room for development.

The cartridge logic valve is easy to integrate: multiple components can be concentrated in a block body to form a hydraulic logic control system, which can reduce the weight of the system composed of conventional pressure, direction and flow valves by 1/3 to 1/4, and the efficiency can be increased by 2% to 4%.

Product specification

Company details

Company advantage

Transportation

FAQ