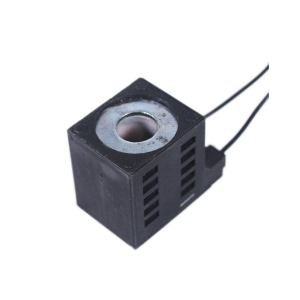

Sumitomo excavator parts SH200/210 hydraulic pump low pressure sensor

Product introduction

Technical introduction

At present, cars have been widely used in people's daily life. There are many kinds of sensors in the automobile to feed back the vehicle information to the driver in time. For example, the oil pressure sensor is one of the many sensors in the automobile. The existing automobile oil pressure sensor needs to be tested after processing, so that the automobile oil pressure sensor can adapt to the high temperature, high pressure and other conditions of the automobile. When testing the automobile oil pressure sensor, it needs constant temperature, high pressure and other conditions. Most of the existing testing devices are single-structure testing devices, which cannot provide comprehensive testing conditions such as constant temperature, air pressure and water pressure. Undoubtedly, multiple testing devices are needed to complete the testing work, which not only increases the cost, but also leads to low accuracy of test results and reduces the quality and performance of products.

Technical realization idea

The purpose of this technology is to overcome the problems that the existing automobile oil pressure sensor testing device can't provide comprehensive test conditions such as constant temperature, air pressure and water pressure, which leads to rising cost and low accuracy of test results, and reduces the quality and performance of products. It provides an oil pressure sensor comprehensive test platform that can simulate the working state of automobile engines and provide comprehensive test conditions such as constant temperature, air pressure and water pressure, which improves the accuracy of test results of oil pressure sensors and reduces the cost of multiple sets of test equipment. The technical scheme adopted by the technology to solve the technical problems is as follows: an oil pressure sensor comprehensive test bench comprises a base, an air control box, a control cabinet, a temperature control cabinet and a water tank, and is characterized in that a water tank and an arm beam are arranged above the base, and an air control box is arranged below the base; the control cabinet is arranged on the arm beam, and control buttons and wires are arranged on the control cabinet. The control button can control the work of the whole test bench, the crocodile clamp is arranged on the lead, the crocodile on the lead clamps the oil pressure sensor on the detection tube, the control button is started to test the oil pressure sensor, the temperature control cabinet is arranged on the arm beam, and a temperature display, a temperature control button and a counter are arranged on the temperature control cabinet.

Product picture

Company details

Company advantage

Transportation

FAQ