Lilalaval solenoid valve coil 12V24V Lilalaval equipment accessories

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works , Advertising Company

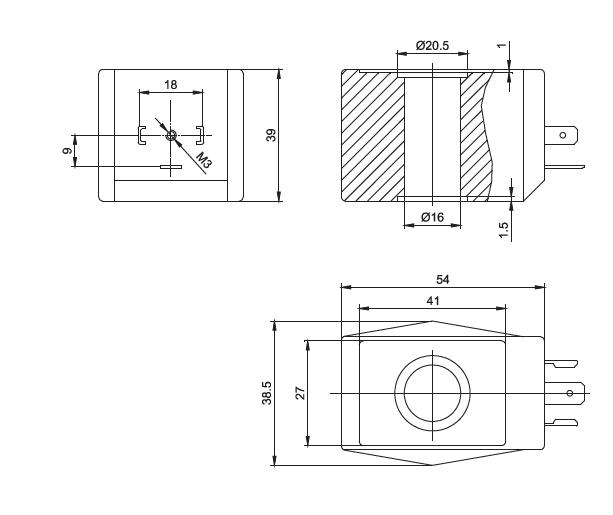

Product name: Solenoid coil

Normal Voltage: AC220V AC110V DC24V DC12V

Normal Power (AC): 26VA

Normal Power (DC): 18W

Insulation Class: H

Connection Type: D2N43650A

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB055

Product Type: AB410A

solenoid valve

The conventional voltage of this coil is AC220V, AC110V, DC24V, DC12V and conventional power AC 26VADC 18W

The insulation material of each insulation level has a corresponding limit allowable working temperature (the temperature of the hottest spot of the motor or transformer winding). When the motor or transformer is running, the temperature of the hottest spot of the winding shall not exceed the specified value, otherwise the insulation material will accelerate aging and shorten the life of the motor or transformer. The thermal classification of the motor refers to the heat resistance grade of the insulation material used, which is divided into A, E, B, F, H, C, N and R grades. The allowable temperature rise refers to the limit that the temperature of the motor rises compared with the ambient temperature. The insulation level of the coil is H-class. In electrical equipment such as generators, insulation materials are the weakest link. Insulating materials are especially vulnerable to high temperature, which accelerates aging and damage. Different insulation materials have different heat resistance, and electrical equipment with different insulation materials has different high temperature resistance. Therefore, the general electrical equipment is required to work at the highest temperature, and the maximum allowable temperature of Class H is 180℃, the winding temperature rise limit is 125, and the performance reference temperature is 145.

The coil connection mode conforms to the German D2N43650A standard

One: Influence of raw materials of electromagnetic coil on performance.

The quality of plastic-coated materials has an influence on the appearance, temperature resistance and waterproof performance of electromagnetic coils. The quality of enamelled wire material has an influence on the temperature resistance, electrical strength, power stability and service life of electromagnetic coil.

Two: Damage reason and judgment method of solenoid valve coil

1, the fluid medium is not pure, resulting in astringent spool card, coil damage

If the medium itself is not pure, there are some fine particles inside, after a period of use, fine material will adhere to the spool. In winter, compressed air with water can also make the medium not pure.

When the slide valve sleeve and valve core of the valve body are matched, the clearance is generally relatively small, and it usually requires single-piece assembly. When there is too little lubricating oil or impurities, the slide valve sleeve and valve core will get stuck. When the valve core is stuck, FS=0, I=6i, the current will immediately increase, and the coil is easy to burn.

2, The coil is damp

Coil damp will lead to insulation decline, magnetic leakage, and even cause the coil current is too large and burned, usually in use, need to pay attention to rain moisture-proof work, so as to avoid water into the valve body.

3, the power supply voltage is higher than the rated voltage of the coil

If the voltage of the power supply is higher than the rated voltage of the coil, let the main magnetic flux increase, the current in the coil will also increase, and the loss of the iron core will lead to the increase of the temperature of the iron core, and the coil will be burned out.

Three:How to check and measure electromagnetic coils?

(1) when selecting and using, first, the inspection and measurement of the coils should be considered, and the quality of the coil is determined. To accurately check the quality of the coil, it is often necessary to use special instruments, which are more complex.

In the actual work, generally only on - off check and Q value judgment. When measuring, we should use a multimeter to measure the resistance of the coil, the monitoring value and the original determined resistance or nominal resistance compared, so that we can know whether the coil can be used normally.

(2) The appearance of the coil should be checked before installation.

Before use, also need to check the coil, mainly to check whether there are defects in the appearance, whether there is loose turns, coil structure is firm, magnetic core rotation is flexible, there is no sliding buckle and so on, these are the need to check before installation, for inspection results unqualified coil, can not be used.

(3) the process of the coil is fine-tuned and the fine-tuning should be considered. Certain coil USES are required to fine-tune, because changing coil Numbers is difficult and fine-tuning is easy to manipulate.

For example, the single-layer coil can be moved through a node to move the hard coil, which means that one end of the coil is wound three or four times in advance, and the inductance is changed by a slight adjustment to the position. Practice has proved that this method can fine tune the inductance of ± 2%-3%.

For short wave and ultrashort wave coils, half a coil is generally left for fine tuning. No matter rotating or moving this half coil will change the inductance to achieve fine tuning.

For multi-layer segment coils, if fine-tuning is required, the number of segment coils that can be moved can be controlled to 20%-30% of the total number of circles by moving the relative distance of one segment. After such fine tuning, the range of inductance influence can reach 10 -15%.

For the coil with magnetic core, we can adjust the position of the magnetic core in the coil tube to achieve the purpose of fine tuning.

(4) When using the coil, the inductance of the original coil should be maintained. Especially explosion-proof coil, can not arbitrarily change the shape of the coil, size and the distance between the coils, otherwise it will affect the original inductance of the coil. Generally, the higher the frequency, the fewer coils.

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product Display

![1621410736836777[0]](http://www.solenoidvalvesfactory.com/uploads/16214107368367770.jpg)