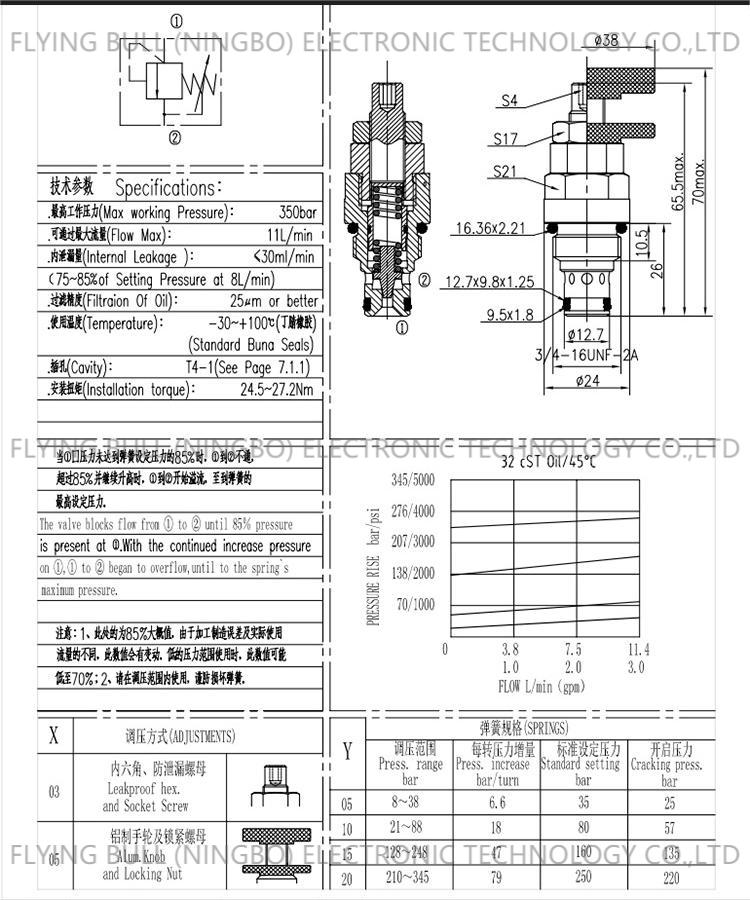

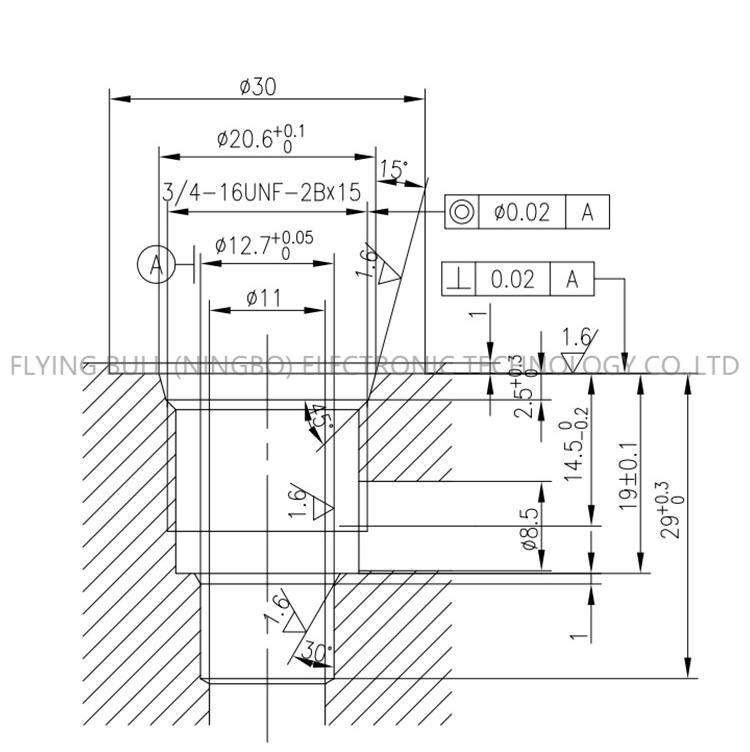

Hydraulic system high-pressure porous relief valve YF08

Details

Materials used:carbon steel

Area of application:petroleum products

Applicable medium:petroleum products

Nominal pressure:Normal pressure (MPa)

Product introduction

1) the method of improving the safety passage of throttle valve and prolonging the service life

The simple way to improve the safety passage of hydraulic one-way throttle valve is the thickened valve seat, which increases the valve seat hole and produces a longer safety passage of throttle valve.

2) Change the inflow method to improve service life.

The open type flows towards the open direction, and the key functions of cavitation and abrasion are on the sealing surface, so that the root of the valve core and the sealing surface of the valve core seat are quickly destroyed; The flow-closed type flows towards the closed direction, and the cavitation and abrasion effects are behind the throttle valve and below the sealing surface of the valve seat, which maintains the sealing surface and the root of the valve core and increases the service life.

3) Change to the method of improving service life of materials.

In order to resist cavitation (the damage is smaller like a honeycomb) and flushing (streamlined small ditch), the throttle valve can be made of materials resistant to cavitation and flushing.

4) Change the structure of control valve to improve the service life.

The purpose of prolonging the service life is achieved by changing the valve structure or adopting a valve with longer service life, such as adopting multi-stage valves, anti-cavitation valves and anti

5) The solenoid valve is stuck.

The matching gap between the rotary pump sleeve of the solenoid valve and the valve core (less than 0.008mm) is very small. Generally all parts are installed. When there is too little residue or grease in mechanical equipment, it is easy to get stuck. The solution can be to stab the rigid wire into the small round hole at the top of the head to make it bounce back. The fundamental solution is to remove the solenoid valve, the valve core and the valve core sleeve, and clean them with CCI4, so that the posture of the valve core in the valve sleeve is flexible. When disassembling and assembling, it is necessary to pay attention to the installation sequence of each component and the external wiring parts, so as to facilitate reassembly and proper wiring. It is also necessary to check whether the oil pump hole of the pneumatic triple is blocked and whether the grease is sufficient.

Product specification

Company details

Company advantage

Transportation

FAQ