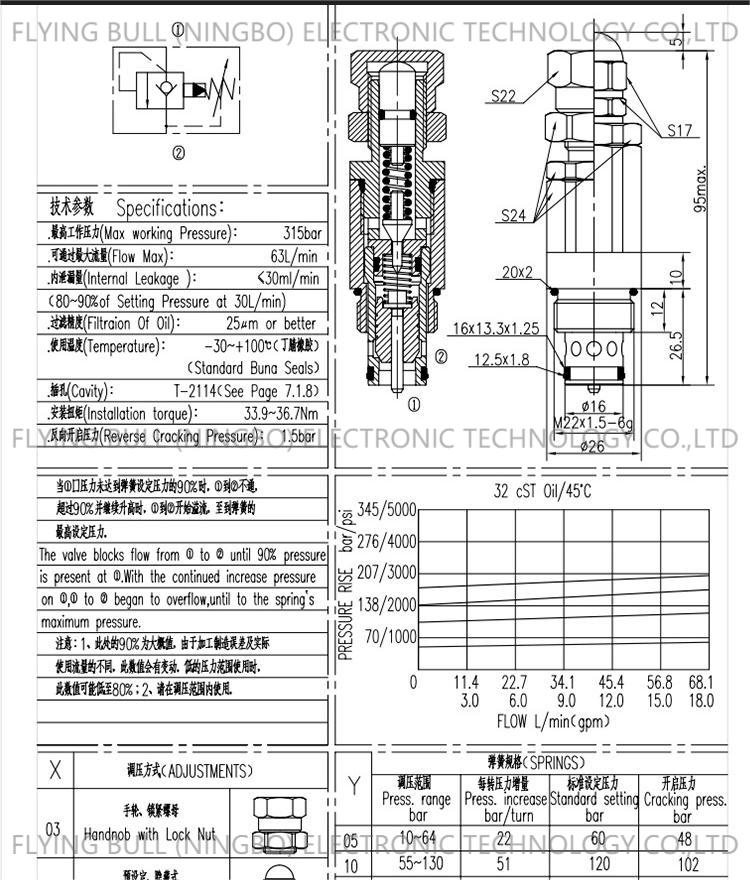

Hydraulic pilot type one-way relief valve FN15-01 for crane

Details

Area of application:petroleum products

Product alias:pressure regulating valve

Applicable medium:petroleum products

Applicable temperature:110(℃)

Nominal pressure:30(MPa)

Nominal diameter:15(mm)

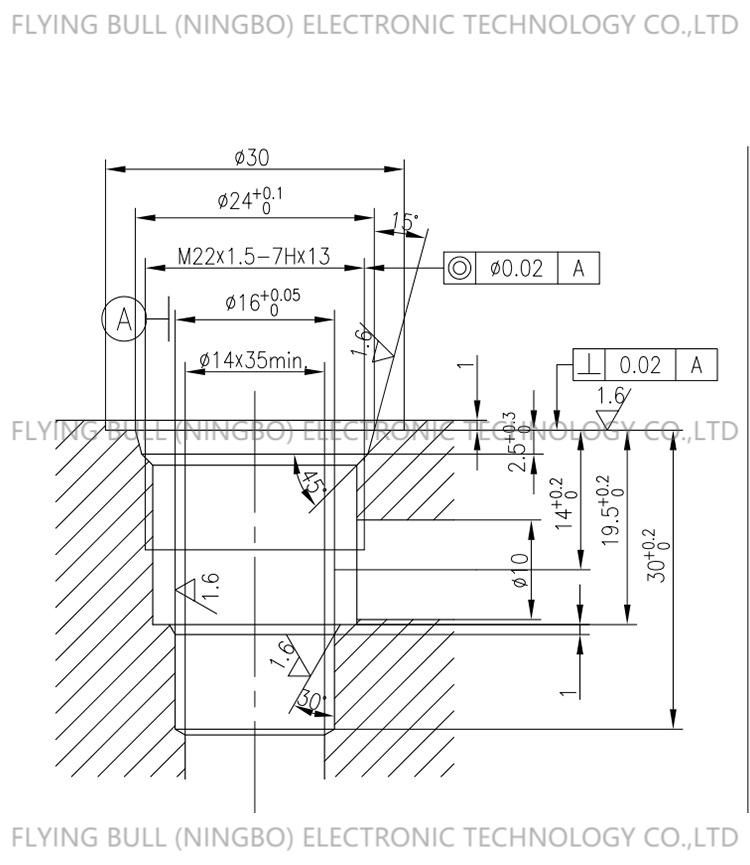

Installation form:screw thread

Working temperature:high-temperature

Type (channel location):Straight through type

Type of attachment:screw thread

Parts and accessories:accessory part

Flow direction:one-way

Type of drive:manual

Form:plunger type

Pressure environment:high-pressure

Main material:carbon steel

Specifications:XYF15-01

Product introduction

1) Working with large opening to prolong life.

Let the regulating valve open as large as possible from the beginning, say 90%. In that way, cavitation, abrasion and other effects are generated on the top of the valve core. With the destruction of the valve core and the increase of the total flow, the corresponding valve should be closed a little more, which will continue to be destroyed and gradually closed, so that all the valve cores can be used flexibly. At the same time, the gap of the throttle valve is large and the abrasion is weak when working with a large opening, which is more than 1 ~ 5 times longer than that when the valve is operated with a middle opening and a small opening at the beginning.

2) In the expansion work

the pressure drop is consumed by setting a packing throttle valve after opening the valve to greatly improve the service life; Turn off the manual valve connected in series on the pipeline until the regulating valve gets an ideal opening degree in operation. It is very simple, convenient and reasonable for pilot relief valve manufacturers to choose this method when the valve is in small opening at first.

3) the method of greatly improving the service life by reducing the specification and expanding the work

According to the specifications of reducing the regulating valve, the opening in the work is expanded. The specific measures are as follows: replace a small and one-size valve, if DN25 is used to replace DN32;; The valve body is unchanged, and the valve seat with small valve seat aperture is replaced.

4) the method of moving damaged parts to improve service life

Move the seriously damaged position to the primary and secondary parts to maintain the sealing surface and throttle surface of the valve core seat.

Product specification

Company details

Company advantage

Transportation

FAQ