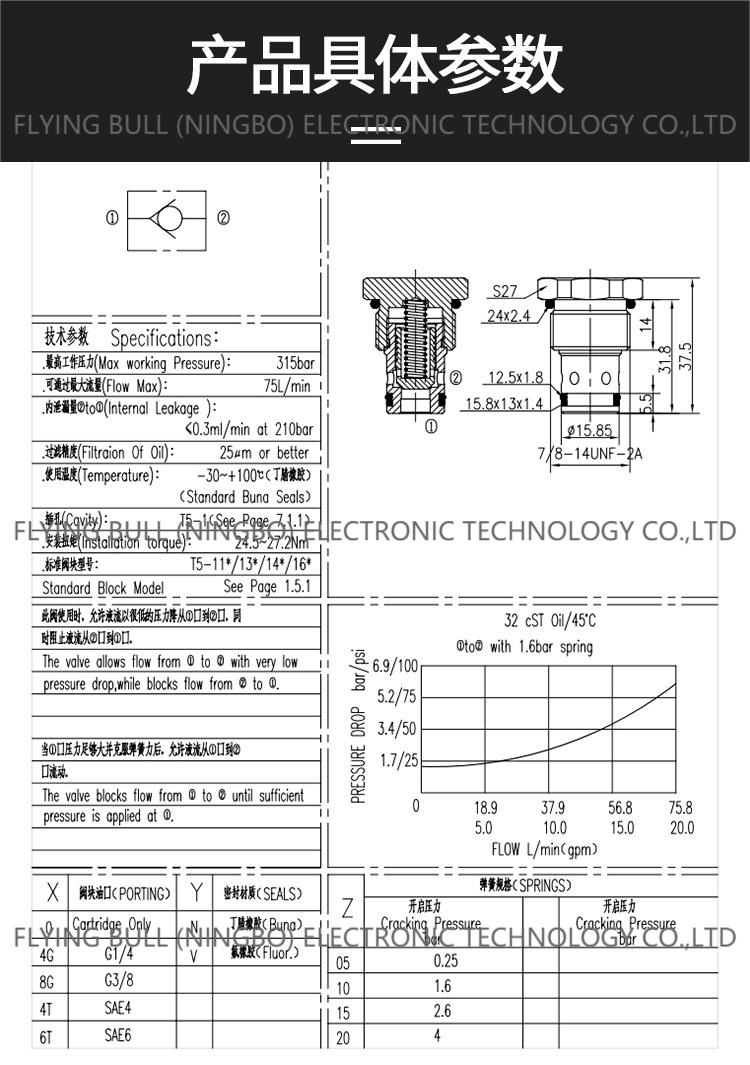

Hydraulic one-way threaded plug-in check valve CCV10-20

Details

Disc form:Lifting valve plate

Number of disc:Monopetal structure

Action form:Quick closing

Type of drive:pulse

Structural style:Swing type

Valve action:non-return

Mode of action:Single action

Type (channel location):Two-way formula

Functional action:Fast type

Lining material:alloy steel

Sealing material:alloy steel

Sealing mode:Soft seal

Pressure environment:ordinary pressure

Temperature environment:one

Flow direction:one-way

Optional accessories:O-ring

Applicable industries:machinery

Applicable medium:petroleum products

Points for attention

Check valve (also known as check valve) refers to the valve that automatically opens and closes the disc depending on the flow of the medium itself to prevent the medium from flowing backwards, also known as check valve, one-way valve, reverse flow valve and back pressure valve. Check valve is an automatic valve, its main function is to prevent the medium from flowing backwards, prevent the pump and driving motor from reversing, and release the medium in the container. Check valves can also be used in pipelines that supply auxiliary systems in which the pressure may rise above the system pressure. Check valves can be mainly divided into swing check valves (rotating according to the center of gravity) and lifting check valves (moving along the axis).

1. Non-return valve: a check valve whose disc rotates around the pin shaft in the valve seat. Disc check valve is simple in structure and can only be installed on horizontal pipeline, so it has good sealing performance.

2. The disc of the check valve is disc-shaped and rotates around the rotating shaft of the valve seat channel. Because the channel in the valve is streamlined, the flow resistance is smaller than that of the butterfly check valve. It is suitable for large-caliber occasions with low flow rate and infrequent flow change, but it is not suitable for pulsating flow, and its sealing performance is not as good as that of the lifting type. Butterfly check valves are divided into three types: single-flap, double-flap and multi-flap. These three types are mainly divided according to the valve caliber, in order to prevent the medium from stopping flowing or flowing backwards and weaken the hydraulic impact.

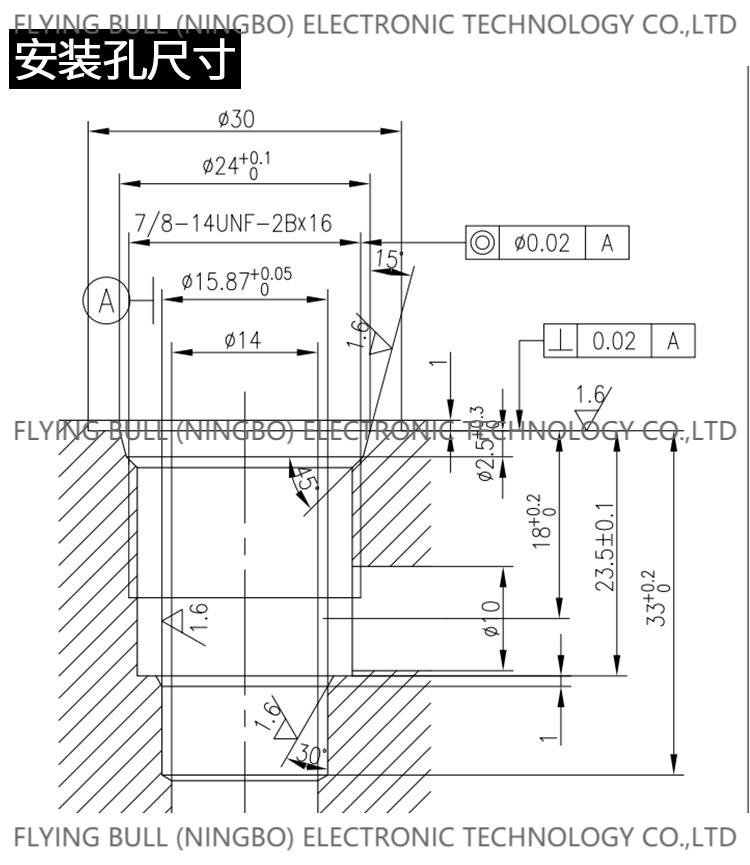

Product specification

Company details

Company advantage

Transportation

FAQ