Hydraulic lock two-way hydraulic control check valve PC10-30 threaded cartridge valve

Details

Dimension(L*W*H):standard

Valve type:Solenoid reversing valve

Temperature:-20~+80℃

Temperature environment:normal temperature

Applicable industries:machinery

Type of drive:electromagnetism

Applicable medium:petroleum products

Points for attention

Check valve is a kind of hydraulic system direction control valve, its main role is to limit the oil can only flow in one direction, can not flow in the opposite direction. The structure and working principle of the check valve are relatively simple, but it is one of the most used components in the hydraulic system, the correct selection and reasonable application of the check valve can not only meet the various functional requirements of different applications of the hydraulic system, but also make the hydraulic system

The design is simplified. This paper introduces the typical application and precautions of check valve in actual hydraulic system.

1 Classification and characteristics of check valve

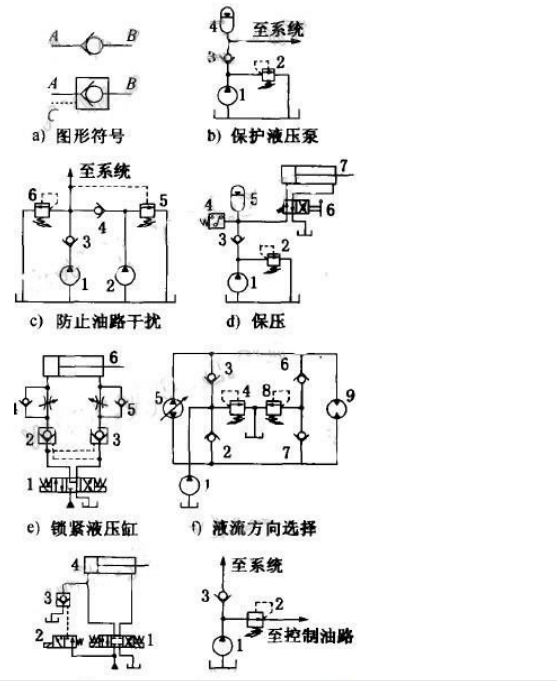

According to its different structural characteristics, check valves are generally divided into ordinary check valves and hydraulic control check valves. The graphic symbol of the ordinary check valve is shown in Figure 1a. Its function is to only allow the oil to flow in one direction (from A to B), and not allow the reverse flow (from B to A); The graphical symbol of the hydraulic control check valve is shown under Figure 1a, its function is to allow the oil to flow in one direction (from A to B), while the reverse flow (from B to A) must be achieved by controlling the oil (C).

Figure 1 Check valve application

The main requirements for the performance of the check valve are: when the oil flows through the check valve, the resistance is small, that is, the pressure loss is small; When the oil flows in the reverse direction, the sealing of the valve port is better and there is no leakage; There should be no vibration, shock and noise when working.

Product specification

Company details

Company advantage

Transportation

FAQ