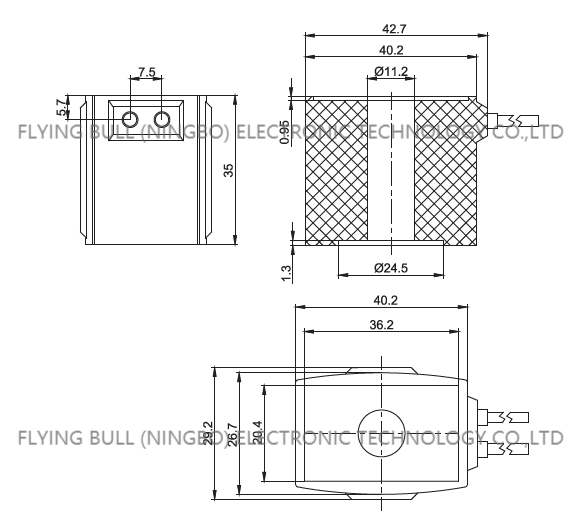

High-temperature lead type solenoid coil of textile machine V2A-021

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works, Advertising Company

Product name: Solenoid coil

Normal Voltage: AC220V DC110V DC24V

Normal Power (AC): 13VA

Normal Power (DC): 10W

Insulation Class: H

Connection Type: Lead type

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB711

Product Type: V2A-021

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Selection and use of electromagnetic coil

1.When selecting and using electromagnetic coils, technical parameters should be checked and measured first, and then the quality should be judged. Only products that meet the requirements can ensure the safety of future use.

2.In order to accurately check and measure the inductance and quality of the coil, special instruments are often needed.

3.The measurement method is complicated. Generally, this kind of inspection is not needed, only the on-off inspection and Q value judgment of the coil are needed.

4.The resistance value of the coil can be detected by using the multimeter resistance file, and then compared with the nominal resistance value. If there is little difference between the resistance and the nominal resistance value after detection, then the parameters can be judged to be qualified.

5.Next, we need to judge the quality of the coil. When the inductance is the same, the smaller the resistance measurement is, the higher the Q value. If multi-strand winding is adopted, the more the number of conductor strands, the higher the Q value.

6.Before the coil is installed, the appearance inspection should be carried out, mainly to see whether its structure is firm, whether the turns are loose, whether the lead joint is loose, whether the magnetic core rotates flexibly, etc. These are all items that need to be inspected before the installation.

7.The coil often needs to be fine-tuned during use, and the method of fine-tuning is very important. For example, a single-layer coil, for the coil that is difficult to move, the method of node movement can be used, so that the purpose of changing the inductance can be achieved.

8.If it is a multi-layer segmented coil, fine adjustment can be achieved by moving the relative distance of one segment. Generally, the moving segmented coil needs to account for 20%-30% of the total number of circles.

9.If it is a coil with a magnetic core, if you want to realize the fine adjustment of inductance, you can achieve the goal by adjusting the position of the magnetic core in the coil tube.

10.When using electromagnetic coils, we should pay attention not to change the shape, size and distance between coils at will, otherwise it will affect the original inductance, and we should not change the position of the original coil at will.

Product picture

Company details

Company advantage

Transportation

FAQ