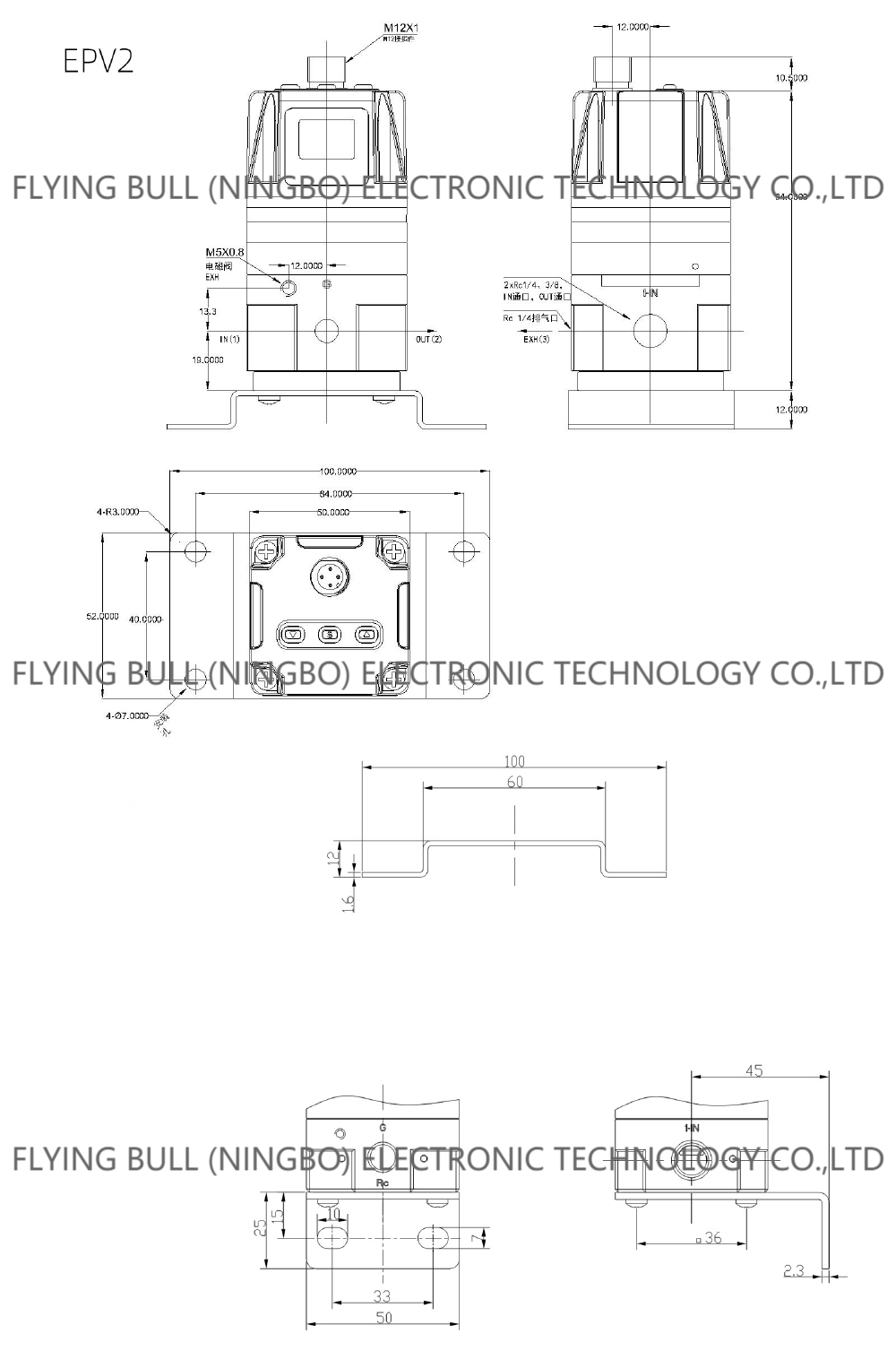

Air Filter Regulator EPV2 Series Electronic Pneumatic proportionervalv

Details

Min supply pressure: Set pressure +0.1MPa

Model Number: EPV2-1 EPV2-3 EPV2-5

Set pressure range: 0.005~0.5MPa

Input signal current type: DC4~20mA , DC0~20mA

Input signal voltage type: DC0-5V , DC0-10V

Output signal switch output: NPN , PNP

DC: 24V 10%

DC: 24V Less than 1.2A

Input impedance current type: 250Ω Less than

Input resistance voltage type: About6.5kΩ

Preset input: DC24Vtype:About4.7K

analog output: "DC1-5V(Load impedance:1KΩmore than)

DC4-20mA(Load impedance:250KΩLess than

Output accuracy within 6%(F.S)"

linear: 1%F.S

Sluggish: 0.5%F.S

Repeatability: 0.5%F.S

Temperature characteristic: 2%F.S

Pressure display accuracy: 2%F.S

Pressure display graduation: 1000graduation

Ambient temperature: 0-50℃

The protection grades: IP65

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

The electric proportional valve is to realize the throttling control of flow by electronic control. The electric control pressure regulating device consists of an air inlet and exhaust regulating switch solenoid valve, a pressure detection sensor and a control circuit. When there is an input signal, the intake solenoid valve is opened, the exhaust solenoid valve is closed, the main valve supplies air to the pilot chamber, and the main valve core moves down to output secondary pressure.

Structural principle editing

When the input signal is increased, the pilot valve 1 of the solenoid valve for air supply is reversed, and the solenoid pilot valve for air exhaust is in the reset state, then the air supply pressure enters the pilot chamber 5 from the SUP port through the valve 1, and the pressure in the pilot chamber rises, and the air pressure acts on the upper part of the diaphragm 2, so that the air supply valve core 4 connected with the diaphragm 2 is opened and the exhaust valve core 3 is closed, resulting in output pressure. This output pressure is fed back to the control circuit 8 through the pressure sensor 6. Here, the output pressure is quickly compared with the target value until it is proportional to the input signal, so that the output pressure changes in proportion to the input signal. Because there is no nozzle baffle mechanism, the valve is insensitive to impurities and has high reliability.Structural principle editing

When the input signal is increased, the pilot valve 1 of the solenoid valve for air supply is reversed, and the solenoid pilot valve for air exhaust is in the reset state, then the air supply pressure enters the pilot chamber 5 from the SUP port through the valve 1, and the pressure in the pilot chamber rises, and the air pressure acts on the upper part of the diaphragm 2, so that the air supply valve core 4 connected with the diaphragm 2 is opened and the exhaust valve core 3 is closed, resulting in output pressure. This output pressure is fed back to the control circuit 8 through the pressure sensor 6. Here, the output pressure is quickly compared with the target value until it is proportional to the input signal, so that the output pressure changes in proportion to the input signal. Because there is no nozzle baffle mechanism, the valve is insensitive to impurities and has high reliability.

Product picture

Company details

Company advantage

Transportation

FAQ