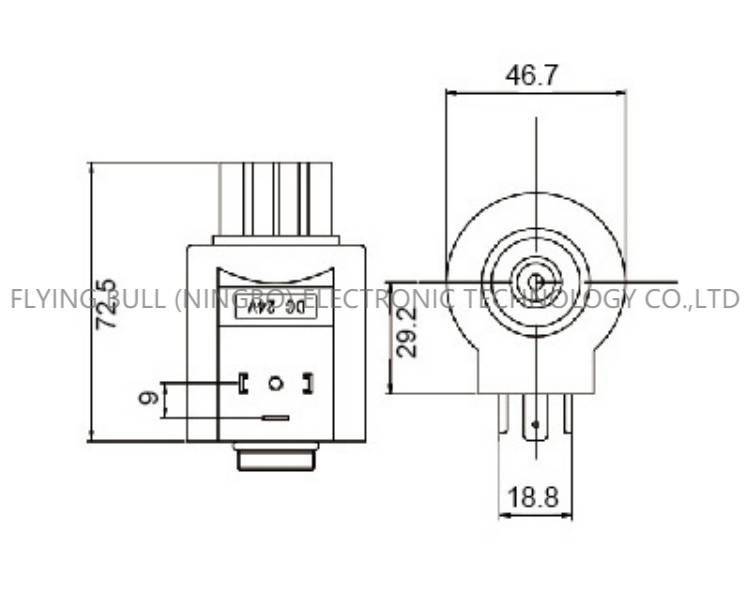

Feiniu series hydraulic solenoid valve coil MFZ8-60Y

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

1, solenoid valve factory solenoid valve coil short circuit or open circuit:

Detection method: firstly, measure its on-off with a multimeter, and the resistance value approaches zero or infinity, which indicates that the coil is short-circuited or open-circuited. If the measured resistance is normal (about a few tens of ohms), it can't be said that the coil must be good (I once measured the resistance of a solenoid valve coil is about 50 ohms, but the solenoid valve can't operate, and everything is normal after replacing the coil), please carry out the following final test: find a small screwdriver near the metal rod passing through the solenoid valve coil, and then energize the solenoid valve. If it feels magnetic, then the solenoid valve coil is good, otherwise it is bad.

Solution: Replace the solenoid valve coil.

2. There is something wrong with the plug/socket:

Fault phenomenon of solenoid valve in solenoid valve factory:

If the solenoid valve has a plug/socket, there may be problems with the metal reed of the socket (which I have encountered), wiring problems on the plug (such as connecting the power cord to the ground wire) and other reasons that the power cannot be sent to the coil. It's best to form a habit: screw the fixing screw after the plug is inserted into the socket, and screw the fixing nut on the coil behind the spool rod.

If the plug of solenoid valve coil is equipped with LED power indicator, it should be connected when DC power is used to drive solenoid valve, otherwise the indicator will not light up. In addition, don't switch the power plugs with LED power indication of different voltage levels, which will cause the LED to be burned out/the power supply (switch to the plug with low voltage level) to be short-circuited or the LED to emit light very weakly (switch to the plug with high voltage level).

If there is no power indicator light, the solenoid valve coil does not need to be polarized (unlike the transistor time relay with DC coil voltage and the intermediate relay with DC coil voltage connected in parallel with diode/resistor leakage circuit < most of these intermediate relays are original ones from Japan >, which needs to be polarized).

Solenoid valve manufacturer's solenoid valve treatment method: correct wiring error, repair or replace plug and socket.

3. Valve core problem:

Fault phenomenon 1: When the pressure of the medium through the solenoid valve is normal, the solenoid valve does not respond when the red manual button of the solenoid valve is pressed (the pressure medium does not change on and off), indicating that the valve core must be bad.

Treatment method: Check whether there is any problem with the medium, such as whether there is a lot of accumulated water in the compressed air (sometimes the function of the oil-water separator is not very great, especially when the pipeline is poorly designed, there will be a lot of accumulated water in the compressed air leading to the solenoid valve) and whether there are many impurities in the liquid medium. Then remove the accumulated water or impurities in the solenoid valve and pipeline. If it doesn't work, please repair it (if you have time, patience and need it or replace the valve core, or simply replace the entire solenoid valve.

Fault phenomenon 2: After inspection, the coil is the original coil and the magnetism of the coil is normal when it is energized, but the solenoid valve still does not act (at this time, the function of the manual button of the solenoid valve may be normal), indicating that the valve core is bad.

Product picture

Company details

Company advantage

Transportation

FAQ