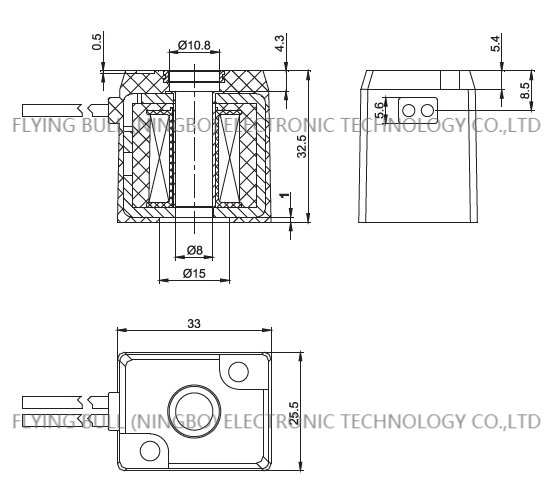

Thermosetting high frequency valve electromagnetic coil 3130H

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works, Advertising Company

Product name: Solenoid coil

Normal Voltage: RAC220V RAC110V DC24V DC12V

Normal Power (RAC): 6.8W

Normal Power (DC): 5.8W 8.5W

Insulation Class: H

Connection Type: Lead type

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB583

Product Type: 3130H

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

How to reduce the circuit fault caused by overheating of electromagnetic coil?

In the circuit, the electromagnetic coil is working for a long time, which can easily lead to overheating and circuit failure. How to reduce the safety hazard caused by overheating of the magnetic coil? This requires people to observe more, pay more attention and take more precautions during the use of this product.

First of all, we need to know the reason why the electromagnetic coil is overheated. It is found that many times, if the forming switch of the protection circuit is not turned on, the dedication coil will not automatically lose power, especially for a long time, which will naturally lead to the problem of coil heating.

1. Make the power supply voltage of the electromagnetic coil conform to the rated voltage. When the power supply voltage is higher than the rated voltage of the coil, it will increase the magnetic flux and cause the current in the coil to increase. If the voltage is lower than the rated voltage of the coil, the magnetic flux will decrease and the excitation current will be unfavorable to the use of the electromagnetic coil.

2. Multi-hydraulic check valve can be used to refurbish the limited coil. For example, the inner wall can be ground again. If some parts inside have aging problems, in order to ensure the sensitivity of product use, it is necessary to eliminate the old ones and replace them with new ones.

3. Transform the electromagnetic start valve. The specific transformation method is to take out the spring inside and rely on the gravity of the valve core to provide the gravity of the electromagnetic coil. The purpose of this is to reduce the water pressure borne by the electromagnetic coil and reduce the heat.

Have you learned the above methods? Usually, when using the electromagnetic coil, we should actively avoid all kinds of circuit failures caused by its heat.

Product picture

Company details

Company advantage

Transportation

FAQ