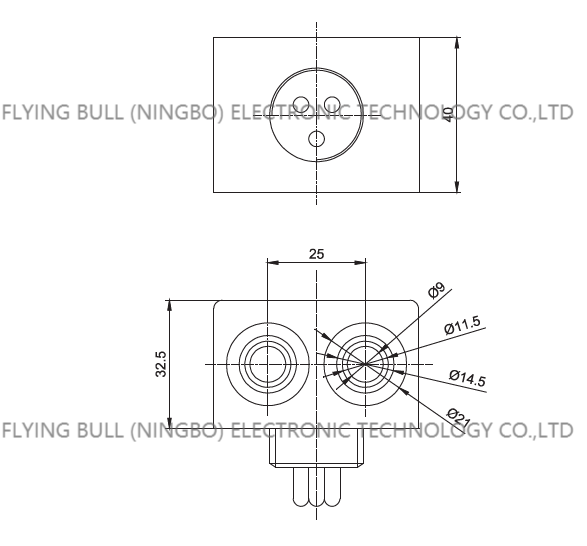

Electromagnetic coil of ABS system for thermosetting vehicle PF2-L

Details

Applicable Industries: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Retail, Construction works, Advertising Company

Product name: Solenoid coil

Normal Voltage: DC24V DC12V

Normal Power (DC): 8W×2

Insulation Class: H

Connection Type: With threaded joint

Other special voltage: Customizable

Other special power: Customizable

Product No.: SB258

Product Type: PF2-L

Supply Ability

Selling Units: Single item

Single package size: 7X4X5 cm

Single gross weight: 0.300 kg

Product introduction

Classification of electromagnetic coils:

First, according to the manufacturing process

According to the manufacturing process, electromagnetic coils can be divided into paint-dipped electromagnetic coils, plastic-sealed electromagnetic coils and potting electromagnetic coils.

1. Impregnated electromagnetic coil

Early electromagnetic coils were mostly used in low-end products.

2. Plastic-sealed electromagnetic coil

Plastic electromagnetic coils can be divided into thermoplastic electromagnetic coils and thermosetting electromagnetic coils.

3, pouring type electromagnetic coil

The process of pouring-sealed coil is complicated and the production cycle is long, so it is not used in general.

Second, according to the use of occasions.

Electromagnetic coils can be divided into waterproof electromagnetic coils, explosion-proof electromagnetic coils (explosion-proof grade: Ex mb Ⅰ/Ⅱ T4) and special electromagnetic coils according to the application occasions.

Three, according to the use of voltage points

Electromagnetic coils can be divided into alternating current, direct current and alternating current rectified by bridge according to the use voltage.

Four, according to the connection mode

Electromagnetic coils can be divided into lead type and pin type electromagnetic coils according to the connection mode.

Installation method of electromagnetic coil:

Insert the electromagnetic coil into the valve spindle of the solenoid valve and fix it in the right direction.

The power pins or leads are connected to the two poles of the power supply, and the grounding pins are connected to the grounding wire (in general, the power supply input is divided into positive and negative poles, and in special cases, it is connected according to the positive and negative signs of the coil).

Characteristics of thermosetting plastic electromagnetic coil:

1. Application scope: pneumatic, hydraulic, refrigeration and other industries, using BMC plastic-coated materials and low-carbon high-permeability steel as magnetic conductive materials;

2. The insulation grade of the electromagnetic coil is 180 (H), 200 (N) and 220 (R);

3. Adopt UL-certified high-quality enameled wire.

Principle of electromagnetic coil:

When the electromagnetic coil is energized, a magnetic field is generated, and the magnetic field generates electromagnetic force.

Structure of electromagnetic coil:

Electromagnetic coil includes grounding pin (metal), pin (metal), enameled wire (including paint layer and copper wire), plastic coating, skeleton (plastic) and bracket (metal).

① Turn-to-turn withstand voltage test: test whether there is leakage between enameled wires.

② Insulation withstand voltage test: test whether there is leakage between the enameled wire and the bracket.

Electromagnetic coils are classified by using voltage:

1. Symbol of AC coil: AC input AC output AC work;

2, DC coil symbol: DC input DC output DC work;

3. Symbol of rectifier coil: RAC inputs alternating current and outputs direct current to work.

Product picture

Company details

Company advantage

Transportation

FAQ