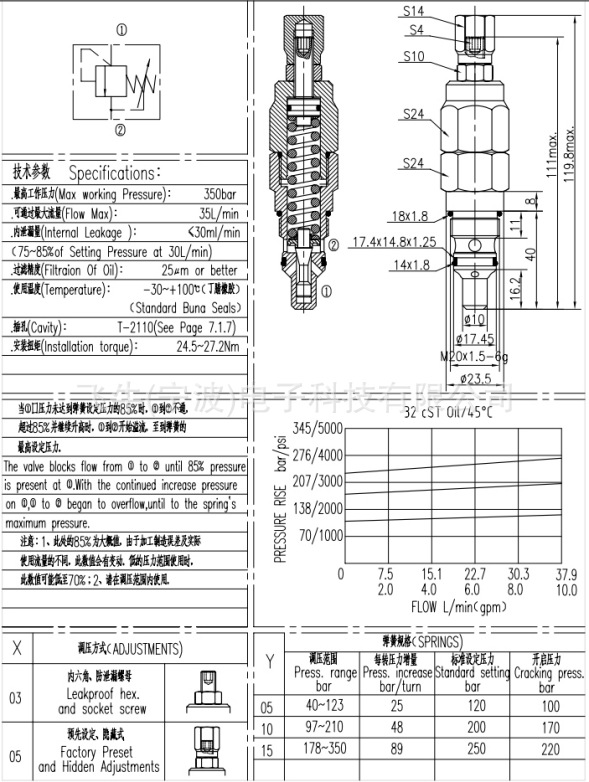

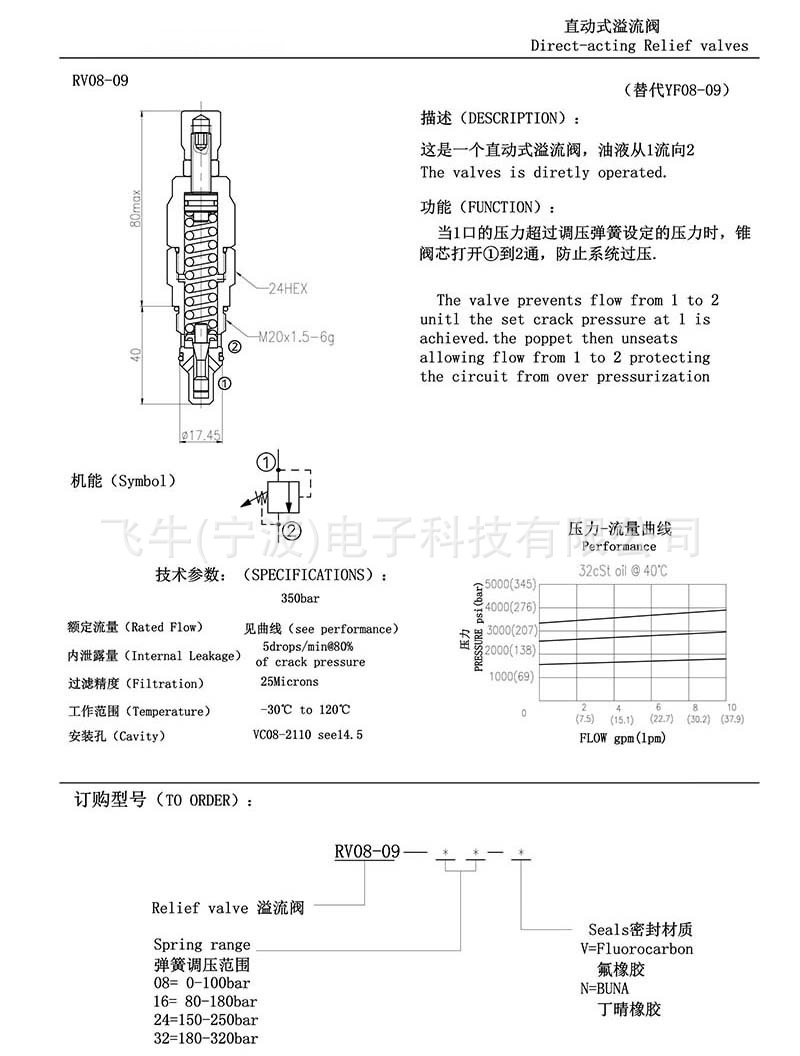

Direct-acting overflow pressure maintaining valve YF08-09

Details

Valve action:regulate pressure

Type (channel location):Direct acting type

Lining material:alloy steel

Sealing material:rubber

Temperature environment:normal atmospheric temperature

Applicable industries:machinery

Type of drive:electromagnetism

Applicable medium:petroleum products

Points for attention

Measures to reduce or eliminate noise and vibration of pilot relief valve

Generally, a vibration damping element is added to the pilot valve part.

The vibration damping sleeve is generally fixed in the front cavity of the pilot valve, that is, the resonant cavity, and cannot move freely.

There are all kinds of damping holes on the damping sleeve to increase damping and eliminate vibration. In addition, due to the addition of parts in the resonant cavity, the volume of the resonant cavity is reduced, and the rigidity of the oil is increased under negative pressure. According to the principle that the components with high rigidity are not easy to resonate, the possibility of resonance can be reduced.

Generally, the vibration damping pad is movably matched with the resonant cavity and can move freely. There is a throttle groove on the front and back of the vibration damping pad, which can produce damping effect when the oil flows to change the original flow situation. Due to the addition of the vibration damping pad, a vibration element is added, which disturbs the original resonance frequency. The vibration damping pad is added to the resonant cavity, which also reduces the volume and increases the stiffness of the oil when it is compressed, so as to reduce the possibility of resonance.

There are air storage holes and throttling edges on the vibration-absorbing screw plug. Because air is left in the air storage holes, the air is compressed when it is compressed, and the compressed air has the function of absorbing vibration, which is equivalent to a miniature vibration absorber. When the air in the small hole is compressed, the oil is filled, and when it is expanded, the oil is discharged, thus adding an additional flow to change the original flow. Therefore, noise and vibration can also be reduced or eliminated.

In addition, if the overflow valve itself is improperly assembled or used, it will also cause vibration and noise. For example, three concentric relief valves are improperly assembled, the flow rate is too large or too small, and the cone valve is abnormally worn. In this case, the adjustment should be carefully checked or the parts should be replaced.

Product specification

Company details

Company advantage

Transportation

FAQ