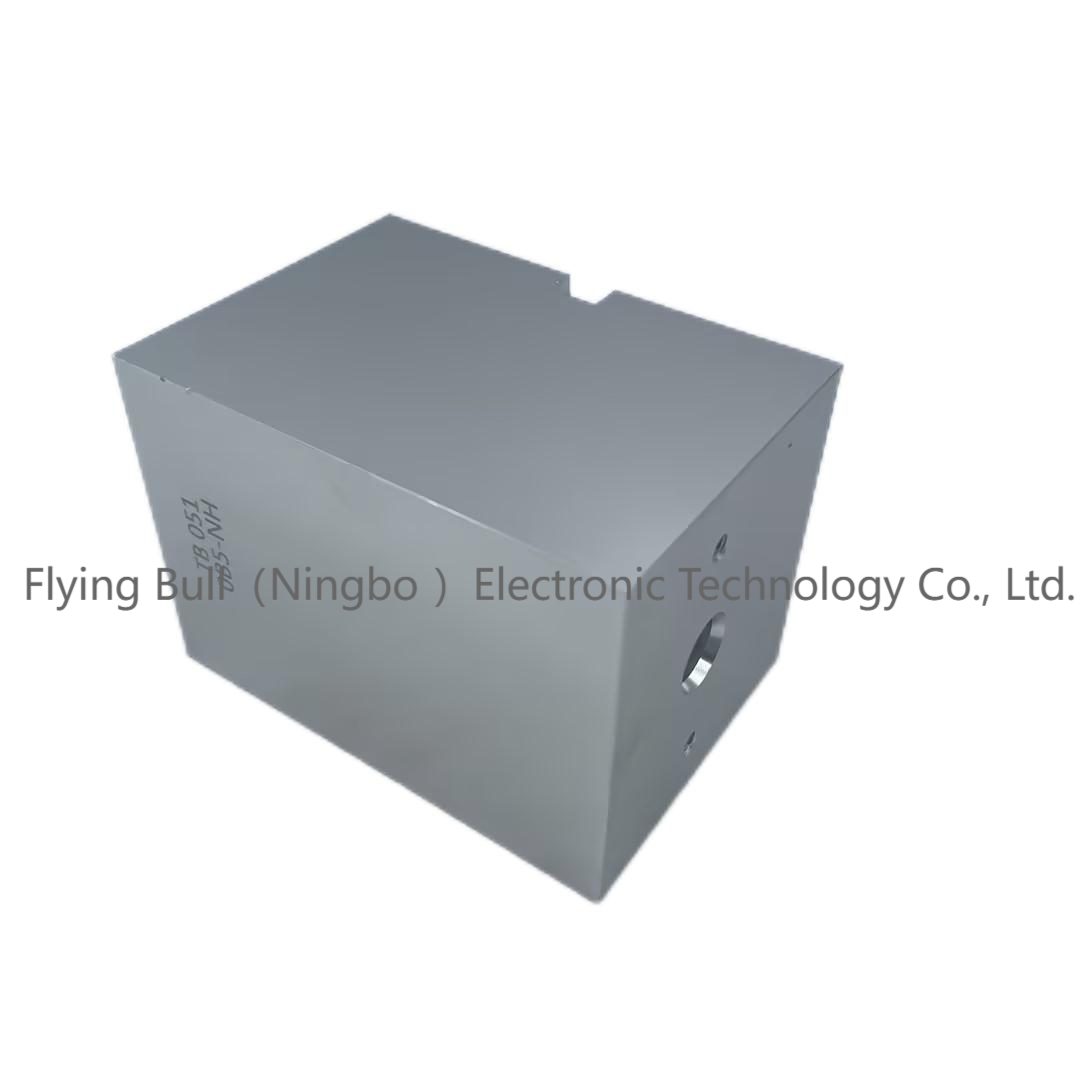

Cylinder hydraulic lock hydraulic element valve block DX-STS-01051

Details

Sealing material:Direct machining of valve body

Pressure environment:ordinary pressure

Temperature environment:one

Optional accessories:valve body

Type of drive:power-driven

Applicable medium:petroleum products

Points for attention

The concrete application case analysis of valve block in steel industry

1. The application of valve block in steel smelting

In the process of steel smelting, it is necessary to control the flow and stop of liquid metal at high temperatures, which requires the use of valve blocks. For example, in the converter steelmaking process, the valve block can control the entry and exit of oxygen and fuel gas, ensuring the balance and stability of the gas in the furnace at high temperatures, thus ensuring the quality of molten steel.

2. The application of valve block in steel plate processing

In the process of steel plate processing, the pressure, flow, temperature and other parameters need to be precisely controlled, and these are inseparable from the valve block. For example, in the cold rolling production line, the coiling speed and rolling pressure can be controlled by adjusting the valve block, so as to achieve accurate control of the thickness and surface quality of the steel plate.

3. The application of valve block in steel conveying

In the process of steel production, molten steel needs to be transported from the blast furnace or converter to the casting machine or continuous casting machine for casting. At this point, the valve block plays a key role. It can control the flow and direction of molten steel, ensure the smooth flow of molten steel into the casting equipment, and prevent molten steel backpouring or leakage, to ensure production safety.

Product specification

Company details

Company advantage

Transportation

FAQ