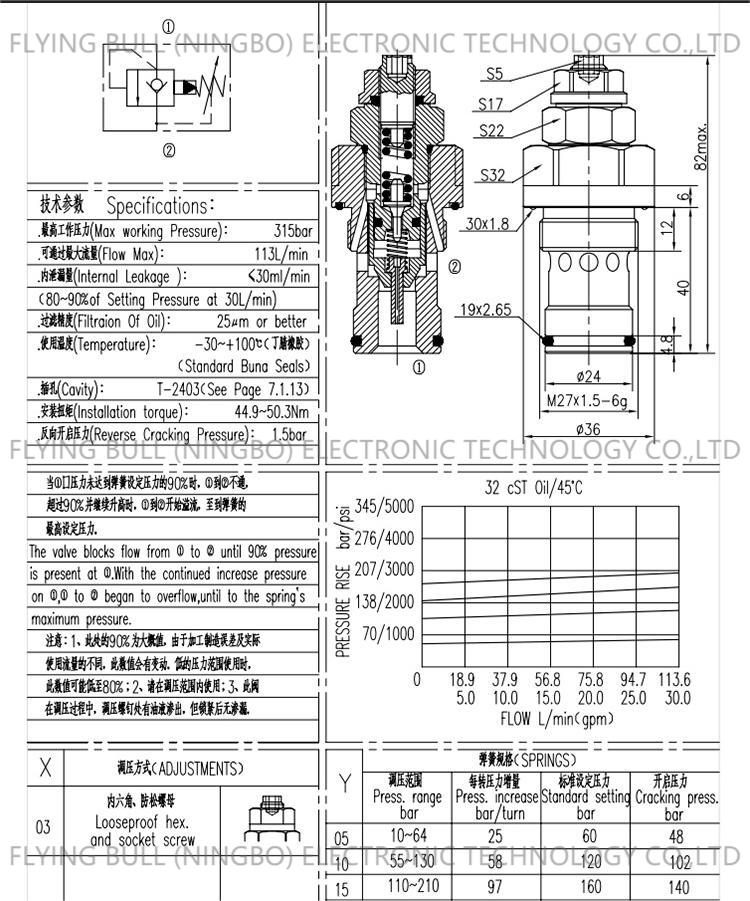

Construction machinery XDYF20-01 pilot relief valve

Details

Area of application:petroleum products

Product alias:pressure regulating valve

Applicable medium:petroleum products

Applicable temperature:110(℃)

Nominal pressure:30(MPa)

Nominal diameter:20(mm)

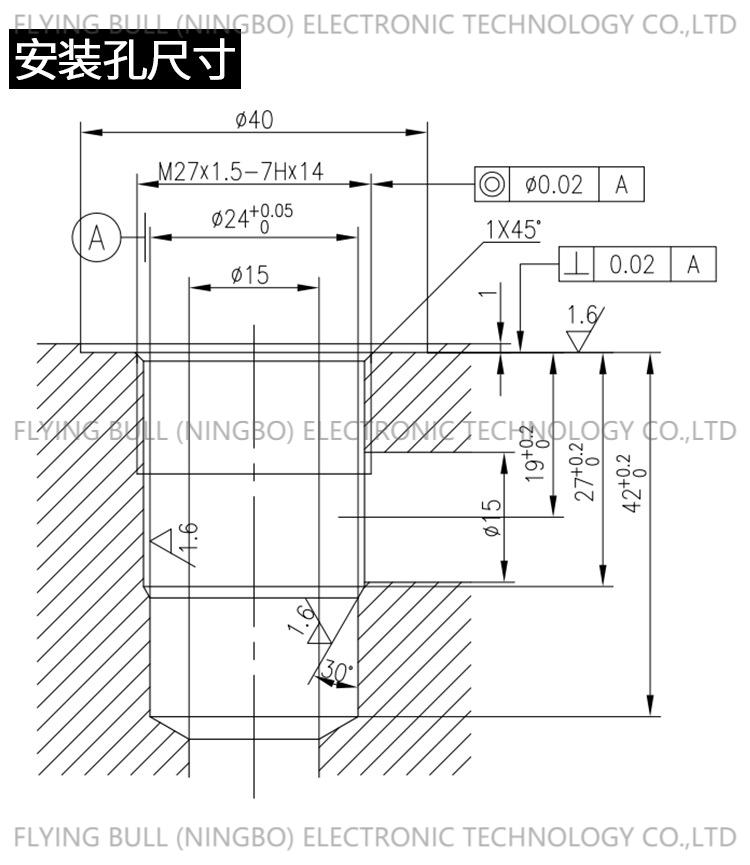

Installation form:screw thread

Working temperature:high-temperature

Type (channel location):Straight through type

Type of attachment:screw thread

Parts and accessories:accessory part

Flow direction:one-way

Type of drive:manual

Form:plunger type

Pressure environment:high-pressure

Product introduction

Voltage regulation failure

The pressure regulating failure sometimes occurs in the use of overflow valve. There are two phenomena of pressure regulation failure of pilot relief valve: one is that the pressure can not be established by adjusting the pressure regulating handwheel, or the pressure can not reach the rated value; The other way is to adjust the handwheel pressure without falling, or even increasing the pressure continuously. There are some reasons for the failure of pressure regulation, besides the radial clamping of the valve core due to various reasons:

First, the damper of the main valve body (2) is blocked, and the oil pressure cannot be transmitted to the upper chamber of the main valve and the front chamber of the pilot valve, so that the pilot valve loses its function of regulating the pressure of the main valve. Because there is no oil pressure in the upper chamber of the main valve and the spring force is very small, the main valve becomes a direct-acting relief valve with very small spring force. When the pressure in the oil inlet chamber is very low, the main valve opens the relief valve and the system cannot afford to build pressure.

The reason why the pressure can't reach the rated value is that the pressure regulating spring is deformed or wrongly selected, the compression stroke of the pressure regulating spring is not enough, the internal leakage of the valve is too large, or the cone valve of the pilot valve is excessively worn.

Secondly, the damper (3) is blocked, so that the oil pressure cannot be transmitted to the cone valve, and the pilot valve loses the function of adjusting the pressure of the main valve. After the damper (orifice) is blocked, the cone valve will not open the overflow oil under any pressure, and there is no oil flowing in the valve all the time. The pressure in the upper and lower chambers of the main valve is always equal. Because the annular bearing area at the upper end of the main valve core is larger than that at the lower end, the main valve is always closed and will not overflow, and the pressure of the main valve will increase with the increase of load. When the actuator stops working, the system pressure will increase indefinitely. In addition to these reasons, it is still necessary to check whether the external control port is blocked and whether the cone valve is installed well.

Product specification

Company details

Company advantage

Transportation

FAQ