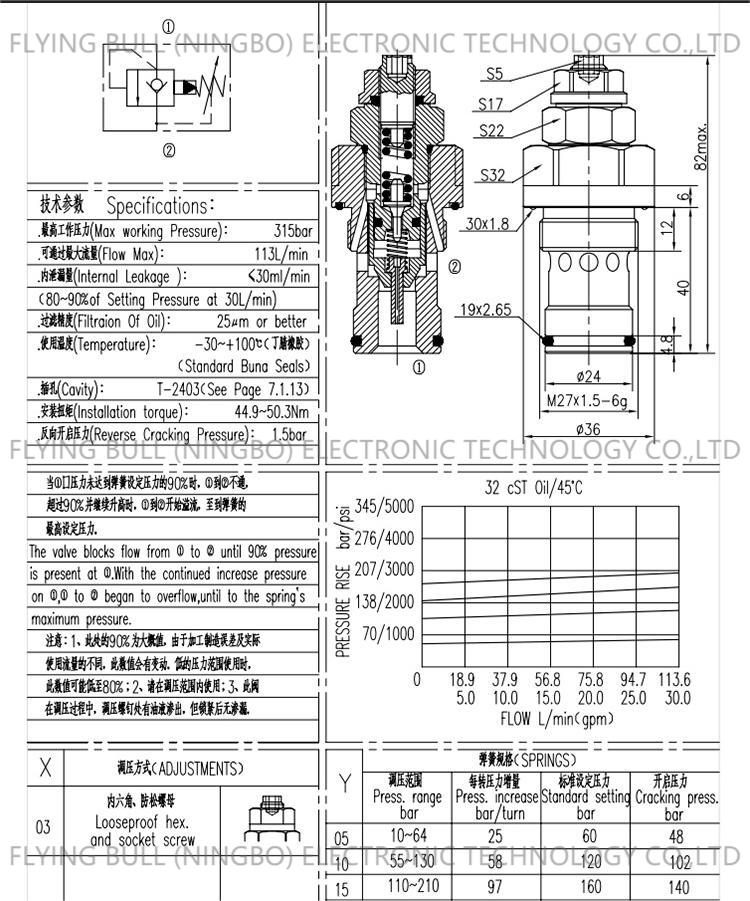

Construction machinery pilot relief valve XDYF20-01

Details

Area of application:petroleum products

Product alias:pressure regulating valve

Applicable medium:petroleum products

Applicable temperature:110(℃)

Nominal pressure:30(MPa)

Nominal diameter:20(mm)

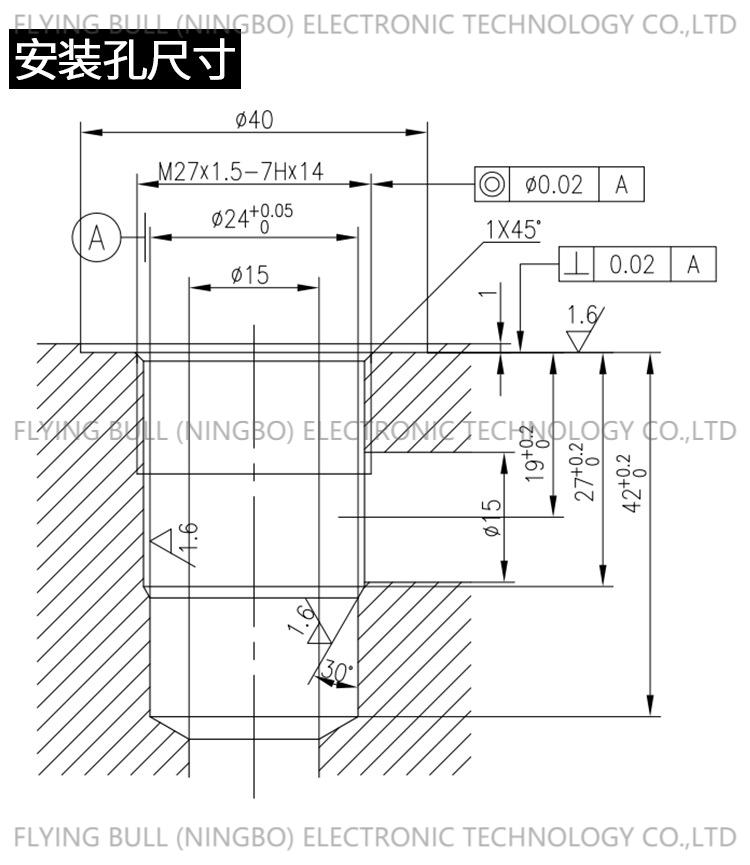

Installation form:screw thread

Working temperature:high-temperature

Type (channel location):Straight through type

Type of attachment:screw thread

Parts and accessories:accessory part

Flow direction:one-way

Type of drive:manual

Form:plunger type

Pressure environment:high-pressure

Product introduction

The role of cartridge valve in hydraulic system is to reduce the production cost of valve block and help users reduce the overall production cost. Cartridge valve in the production is mostly mass production, the size of the valve port is unified, can save a certain production cost. In addition, valves with different functions can use the same specification valve chamber to reduce the processing time of the valve block to reflect the use of cartridge valves. Cartridge valves are widely used in the control of fluids in modern industry. Here are the professionals from Shanghai Yanhao to introduce the main advantages of this equipment.

Cartridge valves are mainly used in the control system of fluid rotation, help control the operation of the fluid, change the flow and direction of the fluid. Common valve products include check valve, relief valve, pressure reducing valve, flow control valve, etc., which plays an important role in fluid control and monitoring. Cartridge valve design and use have a certain degree of versatility, users do not have to specifically according to their own equipment production system to develop products, which also saves a sum of production costs. This design of cartridge valve also makes it widely used in various hydraulic machinery, improving the efficiency of hydraulic machinery.

The use of cartridge valve advantages are mainly small size, low cost, can facilitate the use of users, but also to improve the use of equipment efficiency, help the hydraulic system to correctly control the flow in the system. The mass production of valve blocks can greatly reduce the manufacturing hours for users and improve the operation time of the equipment. According to the mass production characteristics of the product, the integrated block can be tested as a whole before being sent to the user, which improves the efficiency of the inspection.

Product specification

Company details

Company advantage

Transportation

FAQ